Breaking Down The Spindle Manufacturing Process

There is more to the spindle manufacturing process than pure technical considerations; it has been an integral part of the automobile, machinery, and aerospace industries, which depend on it for its varied uses in woodworking and textiles. These industries depend on spindle manufacturing to deliver high-quality spindles for their critical machine components, including precision and engines.

Spindle manufacturing is, therefore, more than a process; it ensures durability and enhances working systems ideal for different industrial applications. It greatly improves productivity, minimizes downtime, maximizes output efficiency, and assures low operation costs. In addition, its capacity to reduce wear and tear minimizes maintenance and repair services.

You must wonder about the process of producing spindles and what makes them ideal for mass-production industries. Well, stay glued to learn in detail.

Understanding Spindle Manufacturing

Spindle manufacturing involves enhancing the overall performance of the machinery. Machining metal rods or bars is the most important part of the process of creating spindles, which are otherwise regarded as the most important component of rotating machinery. Manufacturers use different techniques, like milling, turning, drilling, or grinding, to provide a smooth surface finish. They also introduce different heat treatments to increase the durability of spindles.

The careful, step-by-step spindle manufacturing process ensures that spindles achieve the exacting standards for reliable performance in various industrial applications. Manufacturers also ensure they contribute to machines’ accuracy, longevity, and efficiency.

What Does The Spindle Manufacturing Process Include?

No matter how simple the process of shaping metal bars and rods into spindles may sound, the entire spindle manufacturing process involves a series of crucial steps that begin with selecting the right materials to test the quality of the finished product.

Following a step-by-step process helps the top spindle manufacturer in India stick to top-notch quality maintenance and deliver superior precision components that enhance the reliability of industrial operations.

Material Selection

The initial step in a spindle manufacturing process is selecting the right material, which also contributes to the overall quality of a component. To achieve the desired performance and accuracy, manufacturers use durable, high-quality materials, like alloy steel, high-carbon steel, titanium, a mixture of ceramics, etc., to ensure the chosen materials add to wear resistance, strength, durability, and the ability to withstand heavy loads and high rotational speeds.

Forging or Casting

The two most integral methods in the spindle manufacturing process, forging or casting, have a distinct advantage in cost, precision, and strengthening. Manufacturers choose between forging or casting depending on the specific requirements of spindles. Because the forging process involves shaping metals under high pressure, it produces stronger and more durable spindles with a refined grain structure suitable for high-stress applications.

Similarly, the casting method is applied by manufacturers when there is a need for more complex shapes but in a cost-effective way for large production volumes.

Heat Treatment

In spindle manufacturing, heat treatment is significant in maintaining the spindle’s mechanical properties and boosting its wear resistance, hardness, and strength. Through precisely controlled cycles and heating and cooling procedures, such as quenching, annealing, and tempering, manufacturers modify the internal structure of metals to make them less brittle and use them for rugged applications.

Proper heat-treating methods help manufacturers ensure that the spindles extend the operational lifespan and boost mechanical systems’ overall performance.

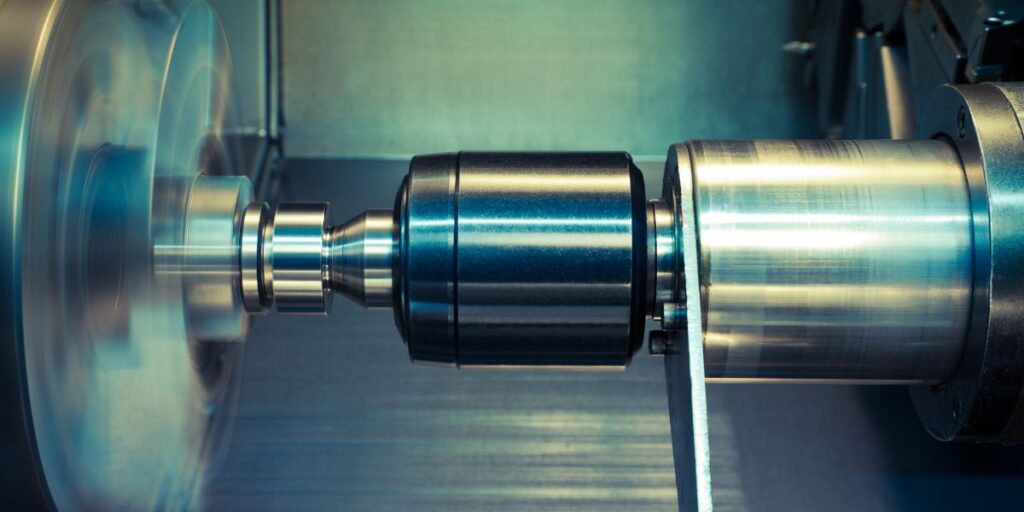

Precision Machining

Precision machining is a critical step in the spindle manufacturing process that enables manufacturers to achieve the desired surface finishing and dimensions. Manufacturers use efficient techniques like milling, turning, and grinding to give the desired shape and size for optimal spindle performance. As a result, the refined spindles with precise specifications are ideal for high loads and ensure minimal friction, smooth rotation, and perfect alignment in the machinery.

1. Cylindrical Grinding

Cylindrical grinding is an efficient finishing technique essential in the spindle manufacturing process. With it, manufacturers achieve a smooth surface finish and high precision on spindle shafts.

It is a manual process that involves rotating the spindle against a grinding wheel, which smoothens all the flaws and helps achieve a uniform surface. This also helps achieve exact spindle dimensions. The cylindrical grinding process improves the spindle’s performance and reduces friction. It also becomes suitable for tight tolerances in industrial settings.

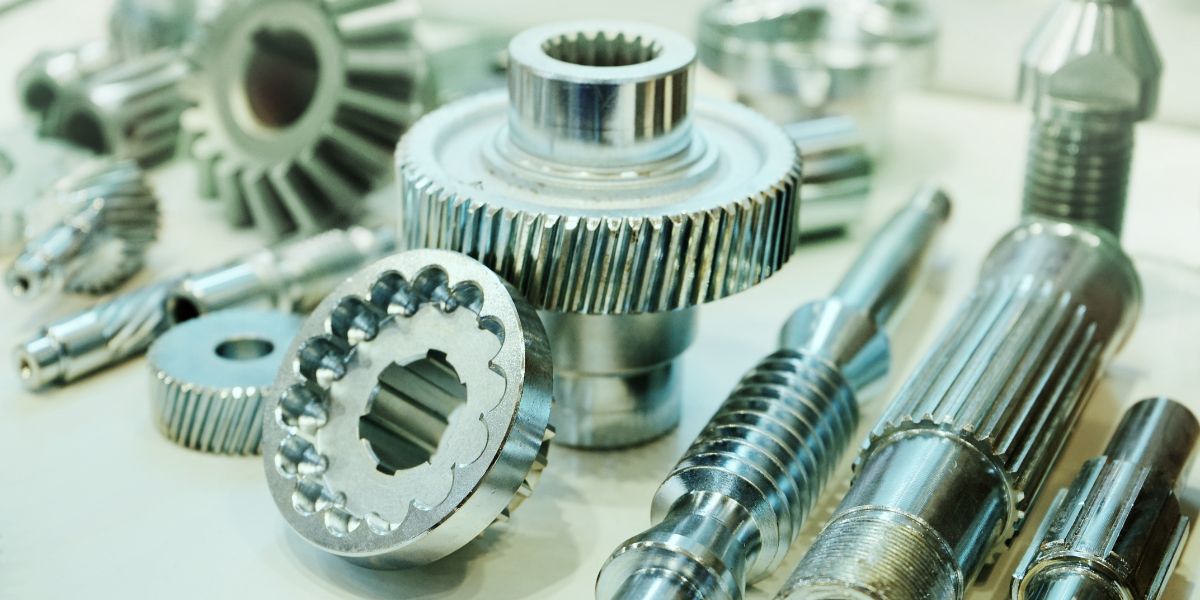

2. Threading and Grooving

Manufacturers use the threading and grooving process to create helical threads and grooves on spindles. The threading process enables the spindle to connect seamlessly with other components, while grooving allows space for fitting and adjusting seals or rings. Both threading and grooving processes play a significant role in maintaining high performance and security.

3. Balancing

Manufacturers must also pay attention to the spindle’s mass distribution and employ the balancing method. By removing or adding material, manufacturers fix the imbalances and ensure minimal vibration during spindle rotation and the least chances for wear and tear.

Surface Treatment

Ensuring the surface is smooth and precise is essential in the spindle manufacturing process. Manufacturers use popular surface-treating methods, such as plating, coating, and polishing, for maximum corrosion and wear resistance. They also improve surface hardness and durability by using techniques like anodizing, hardening, or nitriding. This also ensures the spindles can last under harsh industrial and environmental conditions.

Quality Control

A quality check and rigorous testing are crucial in the final stages of spindle manufacturing. Through quality testing, manufacturers detect defects and implement effective measures to improve the quality of the spindles. Quality control not only increases the accuracy of spindles but also reduces the risk of failures.

Choosing The Best Spindle Manufacturing Process

If you are looking for superior-quality spindles for your heavy machinery, you must be wise when picking your ideal precision components manufacturer. A reliable manufacturer ensures that every step of the manufacturing process is handled carefully and inspected, from selecting high-quality materials to rigorously testing spindle quality.

Manufacturers like Bhansali Techno Components ensure you have access to spindles and other precision components with the highest accuracy, strength, and durability and zero disruptions in operations. Contact us today to learn more about our precision components, manufacturing process, and quality testing procedures.