Spindles Manufacturer In India

Experience seamless operation and enhanced productivity with our meticulously crafted shafting I pins and spindles.

Spindles Manufacturer At A Glance

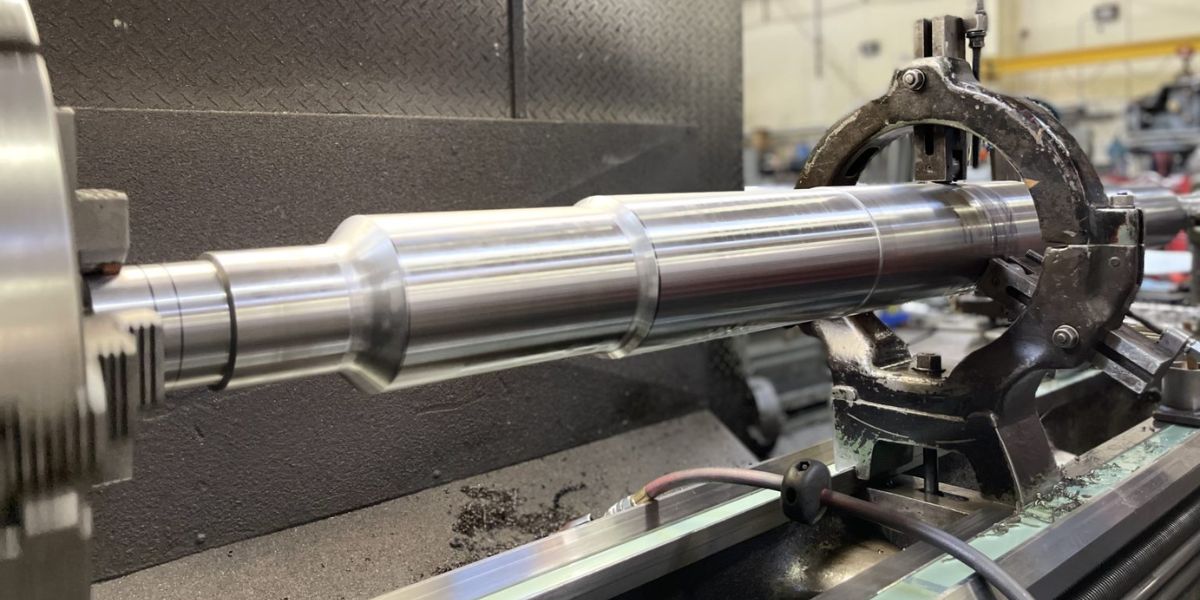

When an excellent shafting spindle is crafted with a performance-enhancing vision, it is not just an ordinary spindle shaft. With an engineering team of great expertise, Bhansali Techno is one of those spindle shaft manufacturers that produce spindle shafts of excellent quality and high precision. It has an efficient design that gives high rotational speeds and a faster production rate. This directly affects a company’s performance and, hence, mass production.

We use raw materials from our bright bar plant and ensure that every shafting I pins are of top quality. Under the surveillance of our experts in material science, the spindle shaft undergoes quality checks at every stage of production. With advanced technology, we ensure that the spindle shafts minimize vibration and are compatible with multiple types of machines. Bhansali Techno Components envisions cleaner energy consumption. Therefore, every spindle shaft produced is designed with energy-efficient features that reduce power consumption.

- Shafting I Pins/ Spindle shafts are customized according to customers' needs.

- We choose raw materials from our bright bar plant

- Advanced technology and quality checks at every stage of production

- The expert engineering team supervises every design and product.

- Spindle shafts with high durability and corrosion resistance.

Spindles Specification

Materials

Crafted from high-grade steel, stainless steel, or durable materials for strength and wear resistance.

Tolerance

Precision machining ensures tight tolerance control (+/- 0.002 inches) for accurate dimensions and fitment.

Surface Finish

Smooth surface finish reduces friction and wear, achieved through precision machining and additional treatments.

Configuration

Available in straight, tapered, or stepped designs to suit various application requirements.

Diameter Range

Offered in diameters from 1/16 inch to 1 inch, providing versatility for different load capacities.

Length

Available in standard and custom lengths to meet specific installation requirements and dimensional constraints.

1. High Strength: CNC machining ensures precise fabrication of Shafting I Pins from robust materials, providing high tensile strength and resistance to bending or deformation.

2. Precision Machining: Advanced CNC machining techniques guarantee consistent dimensions and smooth surface finish, enhancing the reliability and performance of Shafting I Pins.

3. Corrosion Resistance: Utilization of corrosion-resistant materials and surface treatments ensures longevity and durability, making Shafting I Pins suitable for use in diverse environments.

4. Tight Interference Fit: Designed to provide a secure and tight interference fit, ensuring reliable attachment and alignment in mechanical assemblies and structures.

5. Chamfered Ends: Chamfered or rounded ends reduce the risk of damage to mating components and facilitate easier insertion during assembly.

6. Versatile Applications: Shafting I Pins find utility across various industries including automotive, aerospace, manufacturing, and construction, serving as essential components for fastening, alignment, and support in mechanical systems.

Spindles Use In Industries

Electronic Industry

Our Other Products

Handles

Honed Tubes

Machinery Shaft

Hydraulic Shaft

Piston Shaft

Flanges

Auto Components

Industrial Studs

Latest Blogs

The Importance Of Ensuring Quality In The Automotive Sector Quality

Everything You Need To Know About The Best Precision Medical