Best High Tensile Fasteners Manufacturer In India

Experience the difference with Bhansali Techno’s high tensile fasteners – where safety, reliability, and efficiency converge to redefine your construction endeavors

High Tensile Fasteners Manufacturer At A Glance

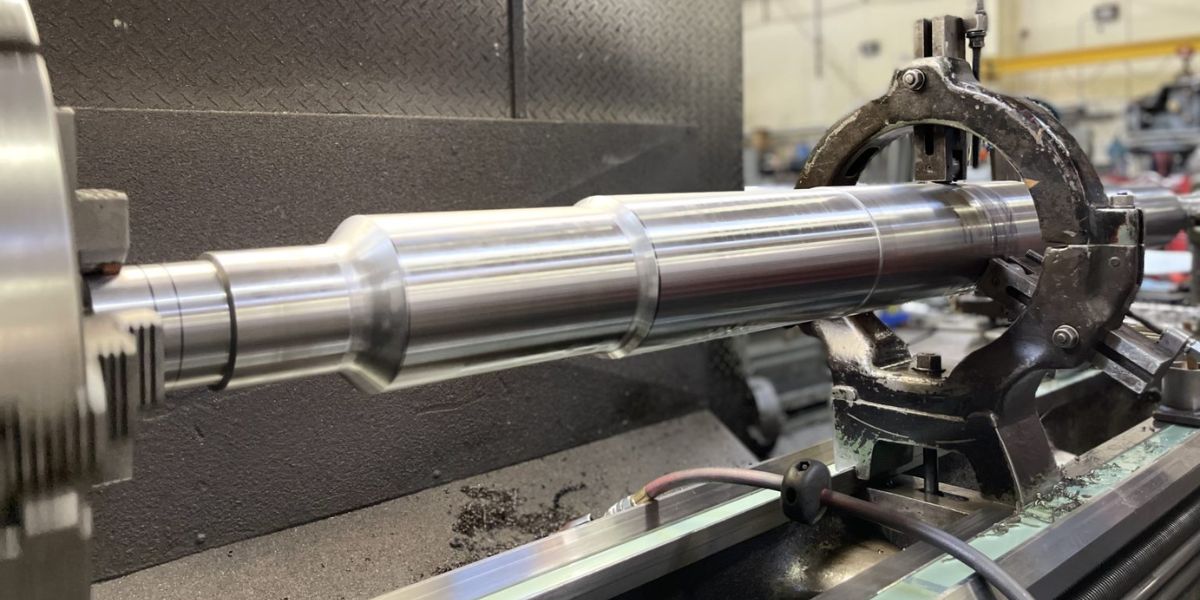

Bhansali Techno is a dominant high-tensile manufacturer in India. We excel in producing machinery components across different industries including aerospace, automobile, truck, etc. Our products are manufactured using CNC Machines, ensuring high precision and supreme quality of high tensile fasteners. We provide high-tensile fasteners like piston rods, valves and pump components, flanges, hydraulic shafts, machinery shafts, stems, and special bushes.

At Bhansali Techno Components, we do not compromise on product quality. Thus, we use raw materials from our plant and ensure quality checks before the products are shipped to our customers. These high-tensile fasteners are built to be corrosion-resistant and to endure high temperatures. We aim to provide the best components that enhance the functions of your machines, and we receive optimum customer satisfaction. Our pride is rooted in the wide network of our partnerships gained through trust and quality service for our customers.

- High-tensile fasteners can be customized according to your unique needs

- We use superior-quality materials for production and no compromise to excellence.

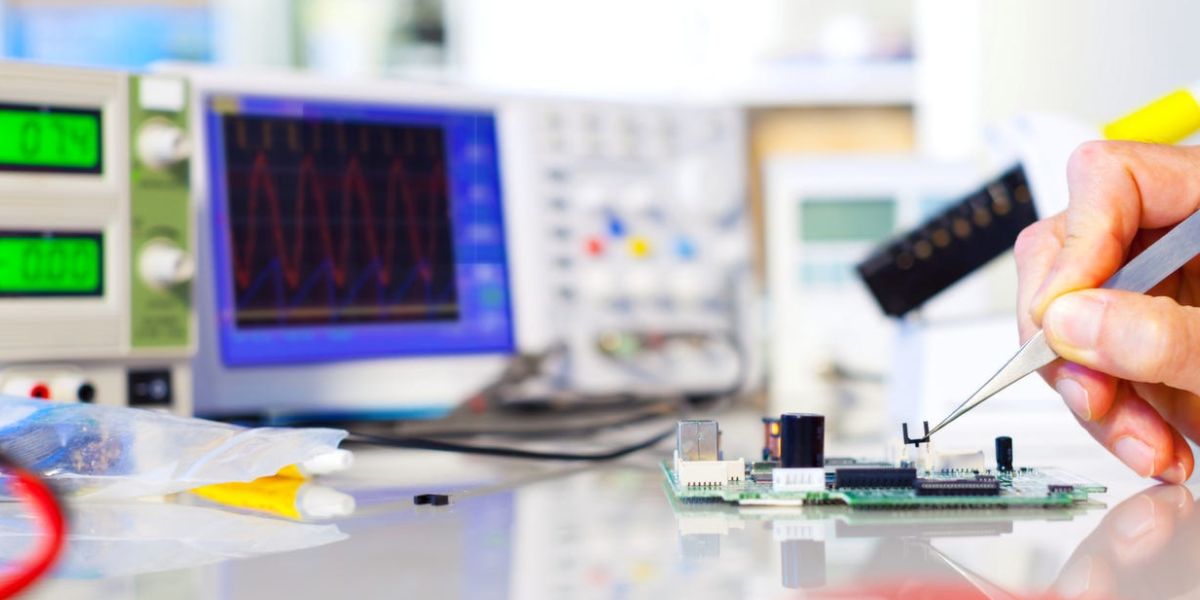

- Advanced technology and material science used by expert engineers

- Products with high durability and corrosion-resistant

- Components that endure high temperature and external environmental changes.

High Tensile Fasteners Specification

Material

Fastener Types

Bolts, nuts, washers, and screws

Size

Surface Finish

Tolerance

Application

- Exceptional Tensile Strength: High tensile fasteners are crafted from premium-quality materials such as alloy steel or stainless steel, known for their outstanding tensile strength. This ensures that the fasteners can endure substantial pulling forces without deformation or failure.

- Durability and Longevity: These fasteners are designed to resist wear, corrosion, and environmental factors, offering an extended service life even in challenging conditions.

- Precise Engineering: High tensile fasteners are manufactured with precision, including accurate threading and consistent dimensions, ensuring easy and secure installation.

- Versatility: Available in a variety of types, including bolts, nuts, screws, and washers, high tensile fasteners can be customized to suit specific project requirements.

- Wide Range of Sizes and Specifications: These fasteners come in various sizes, thread types, and coatings, providing flexibility for diverse applications.

High Tensile Fasteners Use In Industries

Our Other Products

Handles

Honed Tubes

Machinery Shaft

Hydraulic Shaft

Piston Shaft

Flanges

Auto Components

Industrial Studs

Latest Blogs

The Importance Of Ensuring Quality In The Automotive Sector Quality

Everything You Need To Know About The Best Precision Medical