Understanding The Types Of Bearing And Their Uses

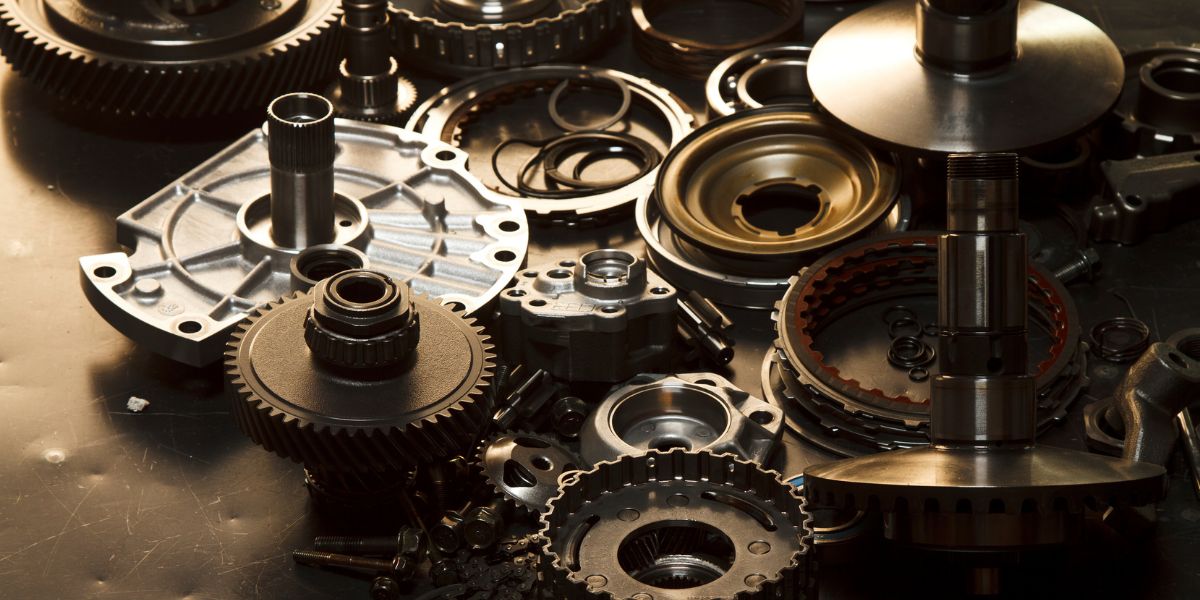

Ever wonder about how it is that machines function so smoothly? While the engineering expertise that was required and the hands that went into the manufacturing play a huge role, a significant amount of credit actually goes to a tiny machine part called a bearing. Various types of bearings are designed for extremely specific and carefully calculated use applications to ensure optimal performance within the complex mechanical system.

But first, let’s understand what a bearing is.

A bearing is a vital machinery component that helps reduce friction and allows the machine to operate effortlessly. This small part is used in almost every machine, from small appliances to big industrial machines.

Different Types Of Bearing And Characteristics

Machine bearings are available in different sizes, designs, and shapes. Although all bearings function the same way, i.e., they provide smooth movement and efficiently manage load, each type is used differently to support the functioning of different machines. You need to understand the types of bearing to know what you need.

Ball Bearings

It resembles steel balls sandwiched between surfaces to minimize friction and support rotational movement. It can handle both axial and radial loads, and, hence, it is widely used in many small and industrial machines.

Due to high rotational speed, it requires less maintenance and operates amazingly. Even in low-load machinery, it handles friction to ensure smooth operation. It is commonly used in automated wheels, hard drives, fans, etc.

Roller Bearings

Instead of a ball-like structure, roller bearings consist of cylindrical rollers that contact the two surfaces with distributed load. They cover a large area, which helps in handling higher radial loads. Roller bearings are perfect for moving heavy objects in slow motion with better stability.

It is commonly used in gearboxes, construction machines like bulldozers and cranes, conveyor belts, etc. By reducing friction, these bearings can manage and move large loads efficiently.

Thrust Bearings

To handle axial loads, thrust bearings are used parallel to the shaft. This helps rotate the equipment in a single direction. Handling the load pressure along the rotational axis helps the machinery parts rotate smoothly.

It is suitable for operating high-speed axial load applications. Thrust bearings are generally used in gearboxes, steering systems, aircraft engines and propellers.

Needle Bearings

It is a roller-bearing type that appears as long, thin, needle-like cylinders. It works in quite a small place where friction needs to be managed. Even in a limited space, it can easily carry a radial load.

Due to its small design, it is suitable for installation in compact machines with limited space. Its applications include many engine components, such as crankshaft assemblies, and car transmissions, and hand-held tools, such as drills.

Magnetic Bearings

Without any physical contact, these bearings work on magnetic fields to support the movement of machinery. They support high-speed machines, such as compressors, flywheels, and turbines.

Minimal wear and tear reduces friction and allows the components to work smoothly. The magnetic field is strong enough to handle the surface load and movement.

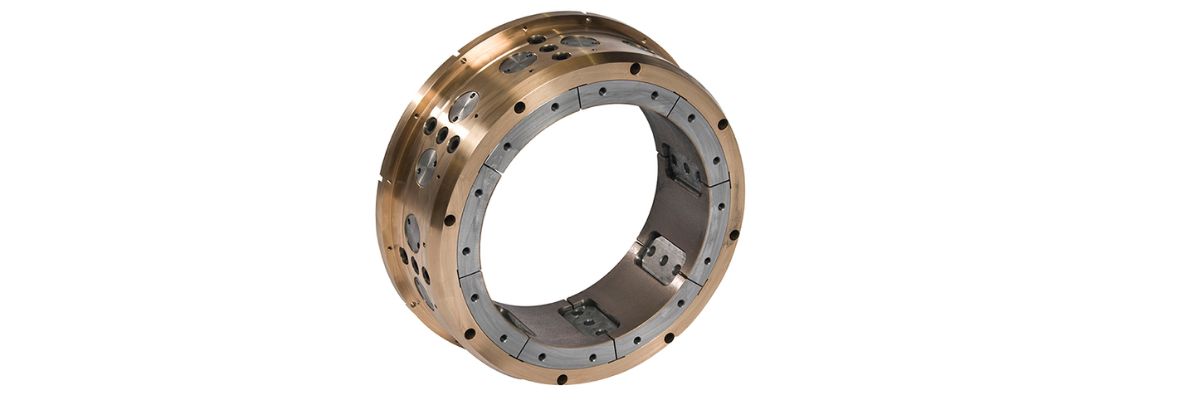

Tapered Roller Bearings

These tapered bearings with outer and inner raceways are sandwiched with conical rollers. They can handle both axial and radial loads in a single direction. The conical rollers distribute the entire load evenly to improve stability.

Due to its unique design, it can easily handle heavy loads coming from different directions. It works effectively even in harsh conditions. It is commonly used in axles, wheel hubs, and other industrial machines.

Spherical Bearings

Spherical bearings, with an outer ring and inner ball structure, handle misalignment between the housing and shaft. Even if these components are not properly aligned, these bearings keep the movement flexible and smooth.

Spherical bearings are commonly used in suspension systems, aerospace, and agricultural machines. They are used for precise and smooth movement.

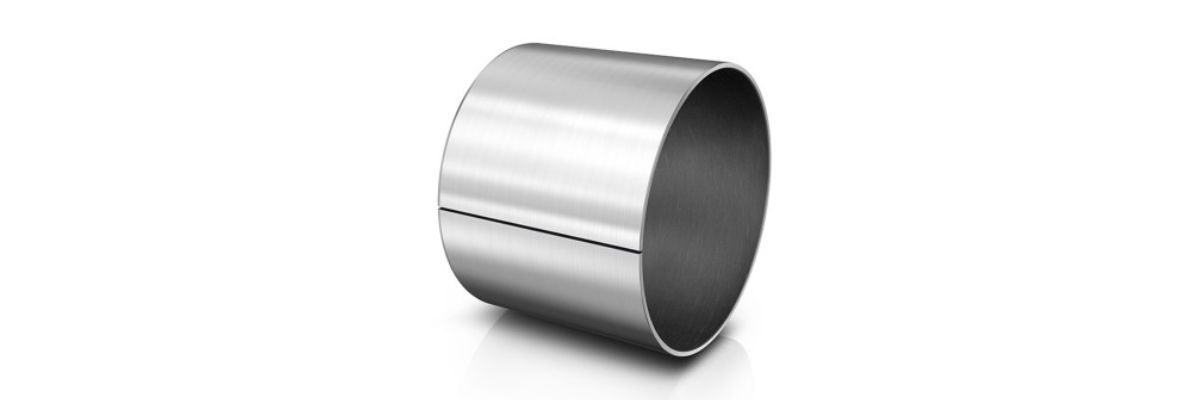

Plain Bearings

It is also called bushings, which consist of sliding surfaces instead of rolling parts. The workings of sliding elements are quite the same as those of rolling elements.

It is used in indoor hinges, in agricultural devices, and by auto components manufacturers. It works excellently in handling low-speed movement. These sleeve bearings are used in many day-to-day applications.

Pillow Block Bearings

Also known as Plummer blocks, it is generally used in constructing buildings. These bearings improve alignment and overall construction component installation within a solid block.

These housings are compelling enough to provide additional protection and support to your building. Its typical applications are conveyors, heavy-duty and belt-driven machines.

Linear Bearings

Consider these bearings if you want your machine to move smoothly in a linear direction. These bearings work great for guiding systems as they oppose rotational motion.

It is commonly used in robotic arms, CNC machines and 3D printers, where linear movement is vital for smooth operations.

Hydrodynamic Bearings

These bearings reduce the level of friction by using a lubrication viscosity between the surfaces. This helps move the parts smoothly without any resistance.

It is used to operate high-speed turbines, significant industrial machines, and generators. Hydrodynamic bearings are used wherever liquid lubrication is required to smoothen the surface and minimize friction.

Flexure Bearings

Instead of sliding or rolling, flexure bearings use the material blending for limited rotational movement of the equipment.

Precision component manufacturers use these bearings for precise output in devices such as microscopes and other scientific components. With low friction, minute movements can be smoothly made with small flexure components.

Choose The Right Types Of Bearing You Need

Simply understanding the various types of bearings is not enough to make an informed purchase decision. Determine your specific requirements to decide what bearings will best suit your machinery to ensure its smooth operation.

While choosing the bearing type, check the load (axial or radial), rotating speed, precision, and rigidity. Once you’re done evaluating your requirements, go ahead and buy bearings from one of the top precision component manufacturers in India like Bhansali Techno Components, and operate your machinery efficiently.