A Comprehensive Guide On Flange Dimensions

Flanges are the connectors in the world of pipes. They help join different sections together, making sure everything works smoothly. Flanges are important for keeping systems safe and leak-free. If you work with pipes, it’s important to know how to read a flange dimensions chart. This ensures everything fits and works correctly.

In this blog, we will look at key flange dimensions and types. We will also talk about how to choose the best flanges for you. This blog also has a clear chart. It will help you pick the right type and size for your project. Let’s get started and make flange dimensions easy for you!

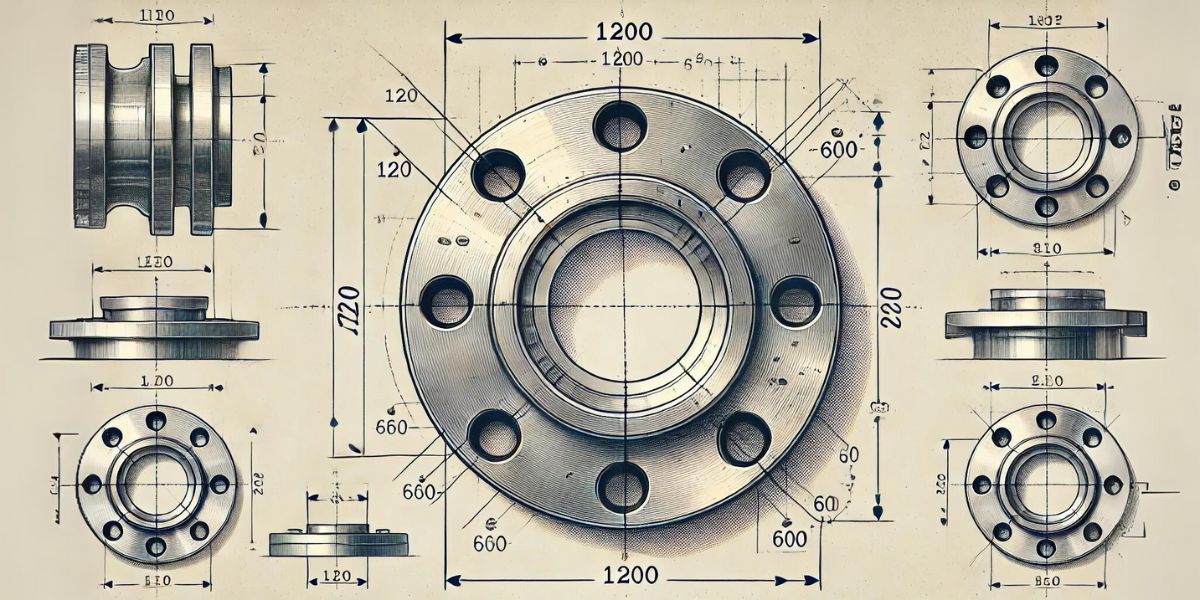

Flange Dimensions Chart

The following chart shows the dimensions of different flange types based on different standards. You can use this table to find the right flange:

| Flange Type | Standard | Nominal Pipe Size (NPS) | Outer Diameter (OD) | Bolt Circle Diameter (BCD) | Number of Bolts | Bolt Hole Diameter |

|---|---|---|---|---|---|---|

| Weld Neck | ANSI | 2” | 6.00” | 4.75” | 4 | 0.75” |

| Slip On | ANSI | 3” | 7.50” | 6.00” | 4 | 0.88” |

| Blind | DIN | 4” | 9.00” | 7.50” | 8 | 0.75” |

| Socket Weld | ANSI | 6” | 11.00” | 9.50” | 8 | 0.88” |

| Lap Joint | JIS | 8” | 13.50” | 11.75” | 8 | 1.00” |

| Threaded | ANSI | 1” | 4.50” | 3.50” | 4 | 0.50” |

| Raised Face | ANSI | 3” | 7.50” | 6.00” | 4 | 0.88” |

| Flat Face | ANSI | 4” | 9.00” | 7.50” | 8 | 0.75” |

Here are some notes for you

- Dimensions are in inches.

- Based on material, manufacturer, and supplier the flange prices may vary.

- For precise pricing, you should contact suppliers directly or visit their websites.

When selecting flanges, always ensure they meet the required specifications for your application, including material, pressure rating, and compliance with relevant standards. There are top-level precision component manufacturers in India that you can trust for your project.

Understanding Flange Types And Dimensions

There are different types of flanges. Each of them is designed for specific applications and requirements.

A. Types of Flanges

Blind Flange

- A blind flange has no opening in the center.

- It seals the end of a pipe. It creates a tight seal.

- It is often used when future access to the pipe might be needed.

Slip-On Flange

- This flange fits over the pipe and is welded on.

- It is easy to install and lines up well with the pipe, making it a popular choice.

Weld Neck Flange

- Weld neck flanges have a long, tapered neck.

- This makes them good for high pressure.

- The neck adds strength and supports the joint.

Socket Weld Flange

- Socket weld flanges fit inside a pipe and are welded around the socket.

- They are often used in small pipes and create a strong connection.

Threaded Flange

- Threaded flanges have threads inside.

- These threads let you screw the flange onto a pipe.

- They are good for systems where welding can’t be done.

- They are often used in low-pressure situations.

Lap Joint Flange

- A lap joint flange works with a stub end.

- This makes it easy to take apart.

- It is often used in pipes that need regular maintenance.

Raised Face Flange

- This flange has a raised area around the bolt holes.

- This helps create a better seal.

- It is often used in high-pressure situations and works well with gaskets.

Flat-Face Flange

- Flat-face flanges have a flat surface.

- This makes sealing easy.

- They are usually used in low-pressure systems.

- They can connect with other flat-face flanges.

B. Key Flange Dimensions

Correct flange dimensions are necessary to ensure pipes fit well and do not leak. Here are the key flange dimensions you should understand.

Outer Diameter (OD)

- Measures the total width of the flange from edge to edge.

- Ensures the flange will fit within the allocated space.

Inner Diameter (ID)

- Corresponds to the size of the pipe to which the flange will connect.

- Proper inner diameter is crucial for flow rate and system integrity.

Flange Thickness

- The thickness of the flange affects its strength.

- Thicker flanges withstand higher pressures, but they are heavier.

Bolt Circle Diameter (BCD)

- Refers to the circle created by the center points of the bolt holes.

- Ensures proper alignment with the bolt used to secure the flange

Number And Size Of Bolt

- Holes Bolts fasten flanges, so the number and size of bolt holes must match the bolts used.

- This is critical for creating a strong, leak-proof connection.

Face Type

- Indicates the type of surface finish on the flange face, such as raised or flat.

- The face type affects sealing performance and compatibility with gaskets.

Pressure Rating

- Represents the maximum pressure the flange can handle safely.

- Choosing a flange with a pressure rating suitable for your system is essential.

Every dimension is essential for the flange to fit correctly and perform well. A small error can lead to leaks or issues.

Factors Influencing Flange Dimensions

Several factors can impact the selection of the right flange dimensions for your project. Flange manufacturers in India are following this.

Pressure Ratings

- Flanges are rated based on the pressure they can withstand.

- Higher-pressure systems require thicker, more robust flanges.

- Common pressure classes include 150, 300, and 600, where higher numbers indicate greater pressure tolerance.

Temperature Ratings

- Flange materials can expand or contract with temperature changes.

- Extreme heat or cold may necessitate special material considerations.

- Make sure your chosen flanges can withstand the operating temperature of your system.

Material Considerations

- Flanges are usually made from stainless steel, carbon steel, or alloys.

- The material you choose will depend on things like-

- Corrosion resistance

- Temperature tolerance

- Pressure requirements

- Fluid type (gas, chemical, liquid).

You can select the appropriate flange dimensions for your specific applications by considering these factors.

Choose The Right Flange Dimension

Selection It is important to understand flange sizes to ensure a good fit and proper function. The right dimensions enhance performance and prevent leaks or failures. Whether you are designing a new system or replacing old components, accuracy is key. It’s recommended that you refer to industry standards and specifications.

Never compromise on quality. Always pick the right things for your project. At Bhansali Techno Components, we provide reliable flange solutions tailored to your needs. Explore our range today and elevate your engineering projects to new heights.