Get Acquainted With Types of Machine Shafts Before You Choose One

Machine Shafts are cylindrical or rod-like structures that are used in mechanical systems.

It is one of the critical elements of a machine. It enhances and profoundly influences the machine’s performance by being responsible for significant power and torque transmissions. Knowing the correct type of machine shaft for your device is essential. Machine Shafts can vary depending on the size and shape of the machinery as well as its specific intended functions. Get to know some of the common types of machine shafts manufactured in industrial components and their uses:

Types of Machine Shafts For Different Industries

Pump Shaft

Disseminating the driver torque to the impellers, which carry it on to centrifugal pumps, is called the pump shaft. It transmits the rotational motion of a motor to the impeller, which in return creates a fluid flow. A

pump shaft can be of different types depending on the specific function and material choice.

Spline Shaft

Designed with splines or grooves along the length of the shaft, the spline shaft is then precisely made to fit into its associating splines of other components. This refined design of a spline shaft allows it to transmit torque while enabling the relative movement seen commonly in vehicles’ driveshafts. Spline shafts can be different depending on their function or any specific requirement.

The standard machine shaft types within spline shafts include parallel key splines, involute splines, crowned splines, and serrations.

Torsion Shaft

These machine shafts are designed to hold out against twisting or torsional loads. When subjected to two opposing twisting (turning) movements, the shaft is considered pure torsion. This motion enables circular shafts to bend without affecting the shaft’s cross-section. The torsion shaft is commonly used in gearboxes or motors.

Quill Shaft

Machine parts like a generator in an engine use a quill shaft as a component to group the parts of an engine that perform the torsional (twisting) loads. It works on a higher stress level compared to a more giant shaft carrying the same amount of torque as the latter.

Intermediate Shaft

The machine shaft used to carry power from one shaft to another is called the intermediate shaft. They perform intermediate functions within a power transmission system and allow for easy removal/reinstallation of CV Axle without much hassle.

Line Shaft

Transmission of power in mechanical systems uses long rotating shafts between the source of energy and the parts of the machine which does the major functions. This element is called a line shaft. It mainly connects the power source to other machine elements or components and transmits this mechanical energy.

However, line shafts were commonly used during the 19th-century factories and lost their popularity with the advent of technology. Line shafts are popularly used in woodworking, machine shops saw or grist mills, and manufacturing.

Drive Shaft

Like its name, the drive shaft is used to pass on the power from machine components like engines to the other parts that are driven using it. For example, the propeller in a boat. The primary function of the drive shaft is to conduct power.

Drive shafts are commonly used in vehicles to commute the torque amongst the machinery parts. However, it is not used in cars that are front-wheel driven.

Propeller Shaft

Shafts used to pass on the energy from the engine to the propeller are called propeller shafts. Its primary function is to transmit the torque from the driving axles to the transfer case and back. It is used in boats and ships to induce forward movement of the transporting vehicle. A propeller shaft is commonly used in boats, ships, and other vehicles like cars, aeroplanes, etc.

Axle Shaft

An axle shaft is used to connect a vehicle’s differential to the wheels and enable it to channel the power to its wheels for rotary functions. This shaft type is commonly used in vehicles (automobiles) and trucks.

Since the axle is responsible for bearing the entire weight of the vehicle, the shaft must also be of good quality to strengthen the component. It is also responsible for maintaining the balance of the car.

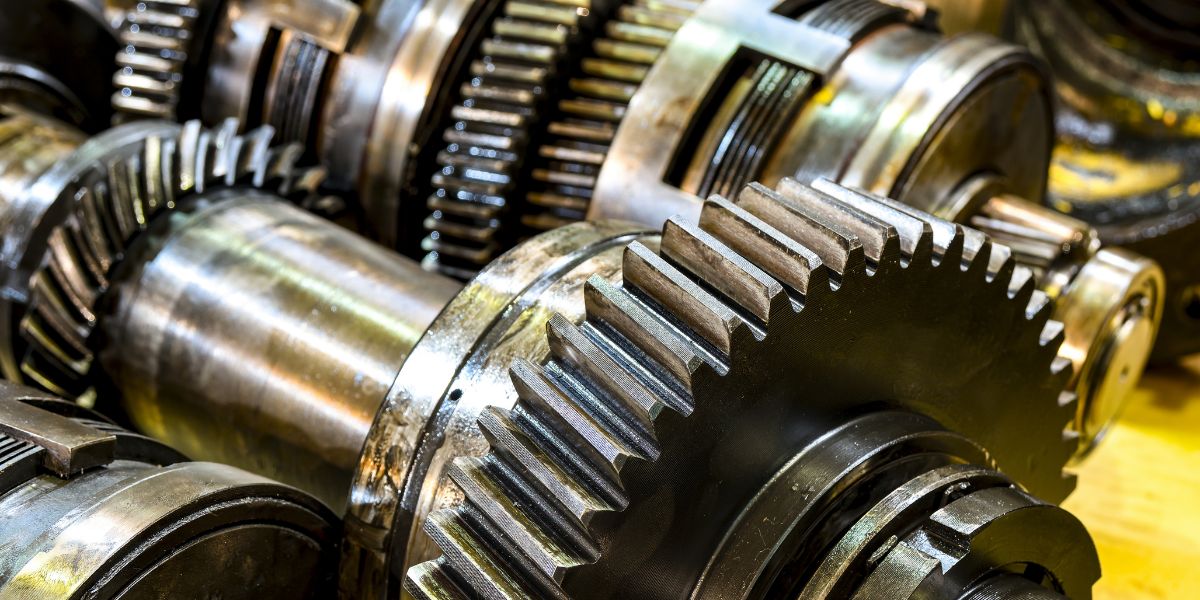

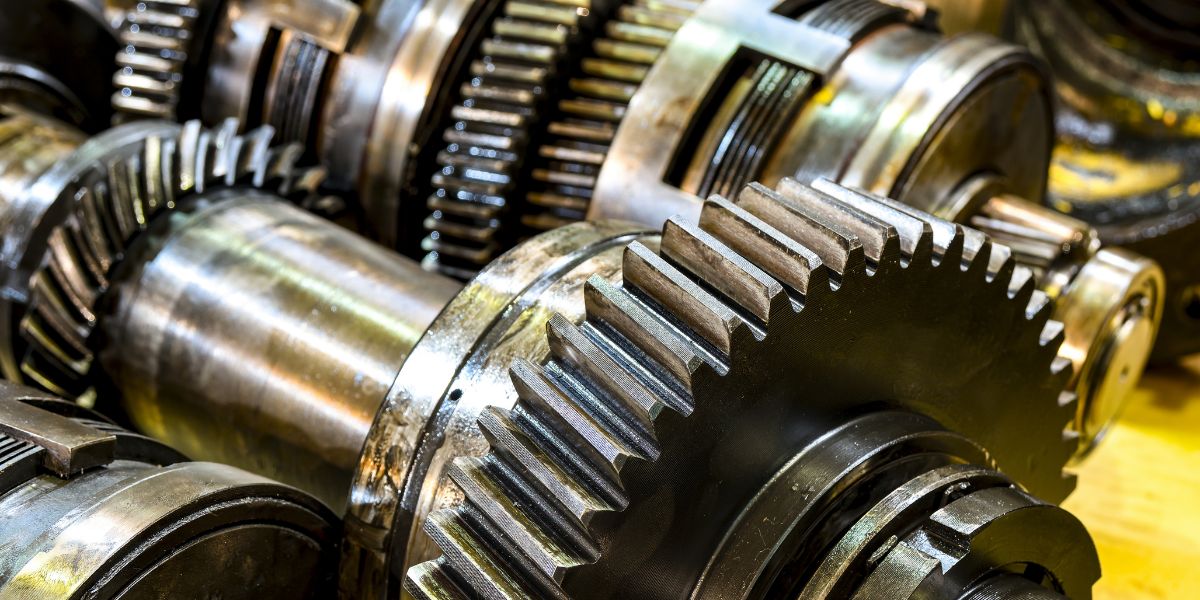

Gear Shaft

The shaft within a gearbox, which is responsible for supplying rotary movements and allowing change of gears, is called the gear shaft. It is the main component of the gearbox as it is also responsible for bearing the stress and torsion of the transmission.

Depending on their specific functions, gear shafts can also be of different types like gears for parallel shafts, gears for intersecting shafts, and gears for skewed shafts. All these gear shafts serve various purposes. Bhansali Techno Components are the top

precision components manufacturers in India that produce different shafts.

Transmission Shaft

The transmission shaft passes the torque, motion, and power from one point of the machine to the other. It mounts gears, pulleys, and sprockets for power transmission.

Depending on the function of shafts, different machine shaft types are used within transmission shafts, including spindle, axle, countershaft, jackshaft, line shaft, etc. It is generally used in vehicles that use manual transmissions.

Crankshaft

A type of shaft is used in the engines of cars and motorcycles for converting the up-and-down motion of the system to a rotational movement. This type of shaft, called a crankshaft, forms the primary component of internal combustion engines.

It has a number of cranks and crankpins that are responsible for the connection of rods to these crankshafts. The major function is converting linear to rotary motion and vice versa.

Camshaft

An important element of the internal combustion engine, the camshaft is used to open and close the valves of the inlet and exhaust in the engine at the right time. It functions with precision strokes and sequence, keeping up the fine machine movement.

The camshaft is handled or operated by a crankshaft which in turn takes the energy from this process to transmit it to the rest of the vehicle. There are three common types of camshafts, which include single overhead camshaft, double overhead camshaft, and pushrod overhead valve.

Stub Shaft

Generally used in one of two axles of front-driven or rear-wheel-driven vehicles, the stub shaft is used to link the CV axle and transaxle. It incorporates a slip yoke that propagates axial movement and supports light or heavy-duty work.

A stub shaft can be of various designs, of which standard designs include the Elliot axle, reversed Eliot axle, lemoine axle, and inverted Lemoine axle.

Rotor Shaft

The rotor shaft is a primary component of the electric motor, which is solely the bearer

of the solid core of the rotor. It carries the electrically generated torque by establishing a positive connection in the transmission. The rotor shaft is generally used in power generation and mining.

A roto shaft can differ depending on the torque, speed control, and efficiency required for the machine it is being used for. General types of rotor shafts include rigid rotors, squirrel-cage rotors, wound rotors, and salient pole rotors.

Looking For The Type of Machine Shaft From Manufacturers?

Get customized machine shafts manufactured with high precision and top-quality materials by Bhansali Techno Components. With over forty years of experience in components and component manufacturing, Bhansali Techno is one of the leading

machine shaft manufacturers in the country. You can get your shafts fabricated according to any personalized designs or requirements.