Difference Between Shaft And Spindle In Industrial Machinery

In the world of industrial machinery and mechanical engineering, shafts and spindles play a crucial role and are an integral precision component for their versatile applications. Shafts and spindles play important roles in machinery, including mechanical operations, power transmission, and so on.

Shaft and spindle share a few similarities, but they also have distinct characteristics that make them quite different.

Understanding the differences, similarities, and specific characteristics of shaft and spindle helps identify the particular components to employ for specific use cases.

At Bhansali Techno Components, we are the leading precision components manufacturer with years of experience.

With an extensive product portfolio and advanced manufacturing process, we can custom-produce shafts and spindles as per your specific requirements without compromising on quality.

What Is A Shaft?

A shaft is a long cylindrical and rotating member of machinery whose primary function is to transmit torque from one part of the machine to another. It helps transmit power or motion between various mechanical components.

Shafts help support axles and other rotating elements in machinery, including pulleys, sprockets, and gears. The shaft plays an important role as a mechanical link between various components, allowing them to function collectively as one unit.

Bearings ideally support shafts to ensure seamless operation, preventing wear and tear.

What Is Spindle?

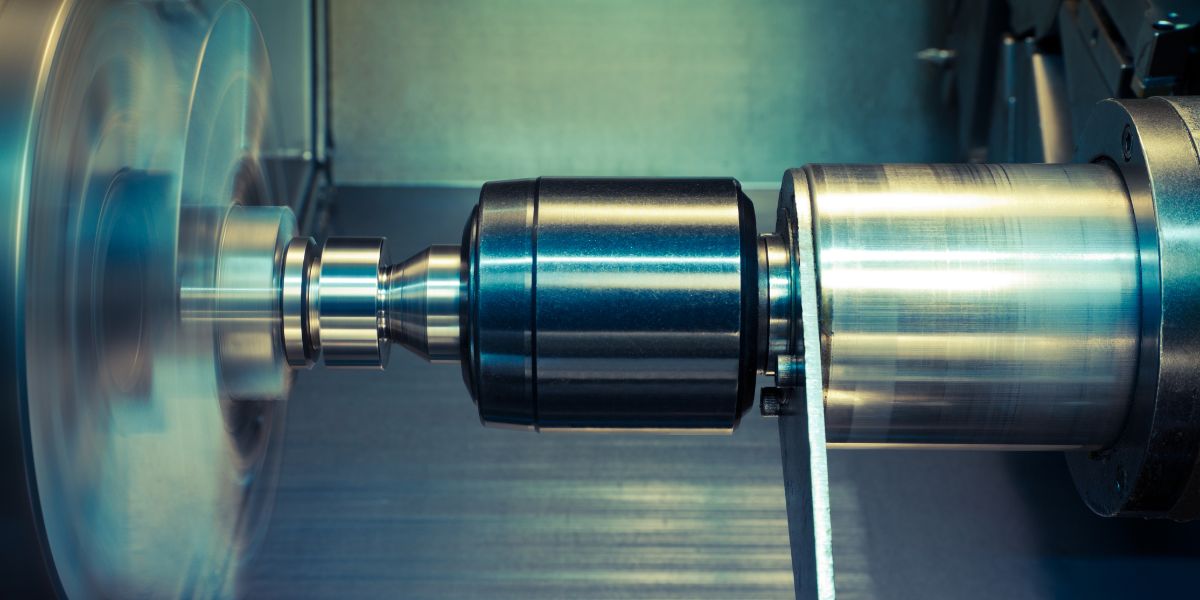

A spindle is a specially designed shaft to perform specialized tasks, mostly in machining operations where high accuracy and precision are essential.

The spindle is commonly used in machines to support and revolve cutting tools, such as lathes, drills, and milling machines. In comparison, the spindle is shorter in length and is purpose-designed for specific tasks.

Ideally, the spindle has a threaded or tapered end to hold the cutting tool securely. As spindles are subjected to heavy-duty rotation at great speeds, it demands rigorous design and a robust manufacturing process.

What Are The Differences Between Shaft And Spindle?

Let us discuss some of the major differences between shaft and spindle elaborately.

| Type | Shaft | Spindle |

|---|---|---|

| Functionality | It primarily functions as a mechanical or transmission link between components, transferring torque from one point to another seamlessly. The shaft also provides alignment support to gears, pulleys, and sprockets. | Its primary function is to rotate a cutting tool in machines, ensuring precise and streamlined operations in tools such as lathes, drills, grinding, and milling machines. |

| Design | It is a long and cylindrical component with a uniform diameter and a generalized design. | These have specialized designs and are, ideally, shorter than shafts. Spindles also have threaded or tapered ends to ensure cutting tools are accommodated. |

| Load Bearing | Another major difference between shafts and spindles is their load-bearing capacity. Depending on the various specific applications, shafts are often subjected to axial or bending loads. | Spindles are often subjected to bending and axial loads due to the fast-rotating forces acting on cutting tools. |

| Precision | Shaft can operate on moderate precision to minimize vibration and ensure seamless rotation. | These require high precision to maintain accurate alignment and streamlined machining results. |

| Speed | They can operate at a vast array of speeds depending on the specific application. | These mostly operate at high speeds to ensure efficient and smooth machining operations. |

| Applications | They are an integral component in various applications, including in various industrial, drivetrain, automotive, and household appliances and machinery. | Spindles are widely used in various industries, including aerospace, metalworking, woodworking, and automotive. |

| Tolerance & Complexity | When compared to spindles, shafts have lower tolerances and precision requirements. | Spindles are used in intricate machining tasks and demand higher precision and tolerance than shafts. |

While the differences between shaft and spindle are many, they’re often found in use in the same or related industries.

Similarities Between Shaft And Spindle

Now, having discussed some of the differences between shaft and spindle, let us look into some of the similarities between them.

- Both are integral machine components used for mechanical operations and are essential for the transmission of power. Bearings typically support both shaft and spindle to protect against wear and tear and for seamless operations.

- Shaft and spindle are manufactured using various materials, including composites, steel, and aluminium. The choice of material depends on the application’s requirements.

- Both of these components require regular maintenance and lubrication to prevent premature wear and tear and ensure seamless operation. Proper lubrication and maintenance help extend their lifespan and avoid wear from high friction and heat generation caused during use. Precision components manufacturers make both shafts and spindles to ensure strength, reliability, and accuracy.

- These components undergo various precision-checking checks like balancing and machining and other quality control measures to meet the required parameters.

- While both shaft and spindle have different functional characteristics, their primary goal is to facilitate rotational movement. They both serve the purpose of transferring torque or rotational power from one component to the other.

Final Thoughts On Shaft And Spindle Difference

While both operate through rotational movement, they’ve their distinct purposes, functionalities, and designs. The difference between shaft and spindle also makes them unique in their way, widely used today in various applications.

Shafts are a highly versatile machining component used to transmit power, whereas spindles are necessary for machining tasks requiring high precision.

Their distinct characteristics and functionalities make them an integral component in various industries for various applications, improving the efficiency and performance of machines in diverse industrial settings.

At Bhansali Techno Components, we are the leading precision component manufacturer from India, manufacturing shafts and spindles of various designs, sizes, and shapes using various materials as per the client’s specific requirements and applications.

If you’re looking for a shaft and spindle for your industrial unit, rest assured Bhansali Techno Component is the name you can trust.

For more information about our product portfolio or to book a consultation call, give us a call today!