A Brief Discussion On Aerospace Parts Manufacturing In India

Aerospace parts manufacturing is one of the key areas of activity in India’s air and space industries. Within this industry, they manufacture engines, fuselages, wings, avionic systems, and other components required by aircraft and spacecraft. This industry is based on precision and advanced materials with strict quality requirements aimed at safety and performance.

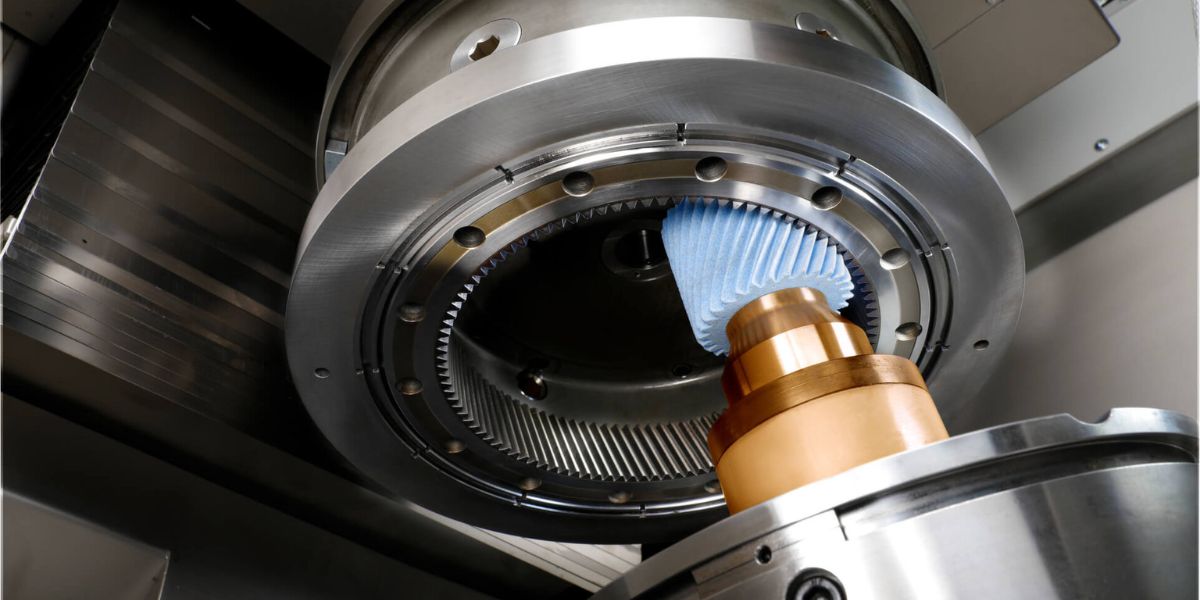

Their products are used in commercial, defence, and space applications. A modern aerospace parts manufacturing company drives innovation in flight and exploration using modern technologies like CNC machining (computer numerical control), composites, or additive manufacturing.

This article will take you to a unique aircraft realm where a number of important aerospace components, as well as factors affecting them, will be presented.

Preponderant Aerospace Components To Be Discussed

1. Engines

The most important segment of aerospace parts manufacturing consists of engines that come in different forms, such as turbofan or turboprop designs that have to encompass high efficiency, reliability, and power. That often implies very complex production methods like 3D printing, which involves the fabrication of intricate lightweight parts. The technique also enables the inclusion of cooling channels, among other highly sophisticated attributes that enhance its performance.

2. Avionics System

An avionics system is an electronic brain for communication, navigation, or monitoring, guiding today’s aircraft while ensuring safe flight by supplying pilots with real-time information besides sending commands from ground control. Making avionics should follow every detail to guarantee that safety regulations can be strictly adhered to; thus, extensive testing, usually including certification processes, has to be done in some circumstances.

3. Landing Gear

Landing gear components are designed to withstand increased stresses when airplanes either take off lands or even taxis. Any shock absorber, for example, must not collapse underuse because it must remain robustly built. These systems are constructed out of special steels and advanced alloys since they work under dynamic loads within various environmental conditions.

4. Control Systems

Control surfaces, together with actuators, help pilots inside an aeroplane to fly it; hence, such extremely responsive devices must be not only accurate but also precise. As a rule, aviation employs hydraulic mechanical or fly-by-wire systems for this purpose. The choice of materials and manufacturing techniques implemented in the process of making control systems ensures that these precision components in the aerospace industry have the desired dependability and performance levels required to maintain the stability and control of an aircraft.

Thus, the aerospace industry uses advanced materials and modern manufacturing technologies to produce components that meet strict safety, performance, and efficiency criteria.

Factors To Be Considered While Choosing The Right Manufacturer

Experience

While selecting a manufacturer, one must consider experience. Aerospace parts manufacturing companies in India that have been in business for a long time are likely to have honed their processes and established rigorous quality control measures. Look at previous work done by the auto part manufacturer, including projects undertaken and clients served; this will help you understand if they can handle complex aerospace specifications characterized by tight tolerances. It would be helpful if someone with past experience in producing such items were chosen since he already knows what kind of technical requirements exist.

Technological And Production Capabilities

In the aerospace industry, precision component manufacture often implies the use of advanced materials and hence demands precision manufacturing techniques. CNC machining, additive manufacturing, advanced composite fabrication, and others are among them. These technologies enable more accurate, better quality overall productivity as well as scalability for precision components manufacturers apart from focusing on R&D capacities regarding novel technologies and market forces.

Supply Chain Support

Finally, supply chain reliability and customer service must also be considered. For instance, dependable suppliers ensure timely delivery, thus helping to link complex schedules together, leading to efficient operations. Moreover, trifling things like lead time or inventory control mechanisms need to be evaluated in terms of logistics issues within such companies.

Also, it is good to have a good customer support team. A quick and knowledgeable customer care unit can save you from some messes or changes during the production of these goods. Ultimately, creating links with an aerospace parts manufacturer that understands customer satisfaction will improve performance outcomes while streamlining operations.

Primary Aerospace Parts Manufacturing

Material Processing

With the use of heat treatment, both mechanical and physical metallic properties are being altered precisely to meet the industry’s standard performance needs. Composite processing is another popular method by means of which materials are used to manufacture and handle different advanced aerospace parts.

Quality Testing And Assurance

Dye penetrant examination, ultrasonic, and X-ray-like methods are implemented to examine part defects or errors minutely. Precision techniques and tools are utilized in this respect to ensure whether the parts meet the standard safety rules and regulations or not. This popular method is termed metrology.

Coatings And Surface Treatments

Anodizing is an intricate approach that causes the surface to be harder and more resistant to corrosion, especially for aluminum parts.Electroplating is another technique for applying functional or protective coatings like chrome or nickel. This process greatly increases the longevity of the components.

Assembly And Fabrication

Adhesive bonding and specialized welding play a great role in assembling materials according to the aerospace standard certification. Metal sheet fabrication involves techniques like forming, bending, and stamping. These processes help develop parts from metal-based sheets. Fabrication and assembling are the two leading phases without which customized aerospace components cannot be prepared.

Additive Manufacturing

Additive Manufacturing, known as 3D printing, has revolutionized the aerospace component industry by developing lighter-weight components with complex geometries beyond conventional fabrication methods’ capability. This leads to less waste while short-circuiting supply chains.

Regulatory Compliance

Precision component makers in the aviation industry must navigate a complex regulatory environment. Non-compliance with these stringent and onerous safety standards can result in significant financial loss and damage to your brand.

Revolving Around Technological Tide

Innovation is an essential element for converting an idea into reality, particularly during a wave of unprecedented technology. New-age innovation challenging existing practices brought by private players has witnessed a rapid expansion of aerospace parts manufacturing via modern technological applications.

We at Bhanshali Techno Components are committed to following cutting-edge technology and ensuring our products meet the highest quality standards to address your technological needs.