Auto Component Manufacturer In India

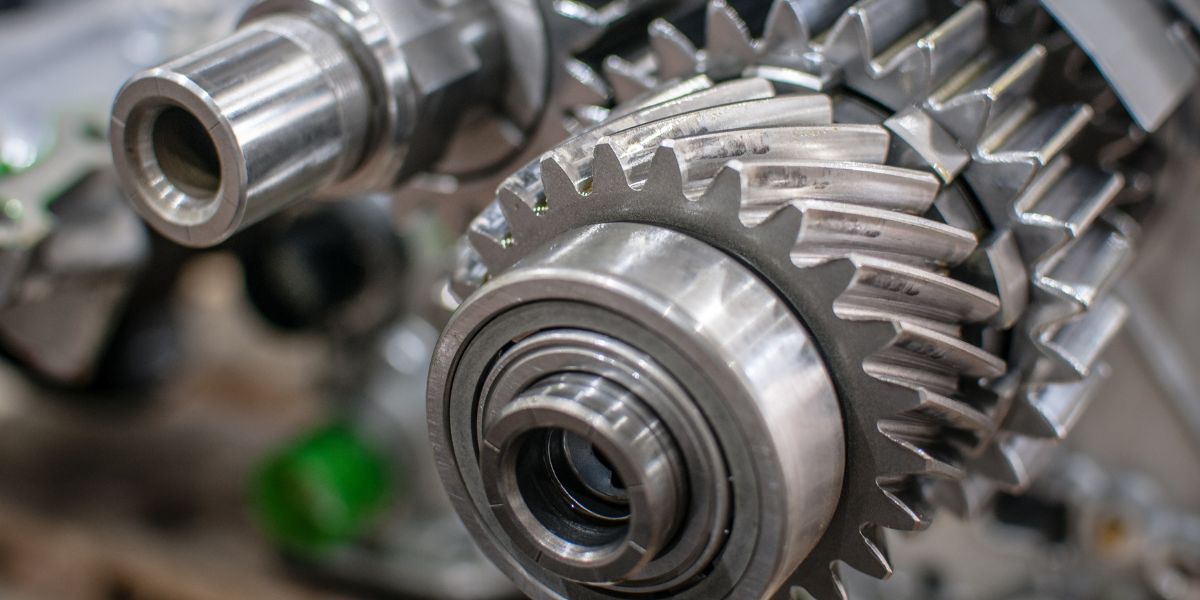

At Bhansali Techno, we specialize in providing high-quality auto components meticulously designed to meet the exacting demands of modern automotive applications

Auto Component Manufacturer In India At A Glance

- Auto components are customizable according to the specific needs of customers

- Top-quality materials from our plant used in manufacturing and production

- Advanced technology and material science used by expert engineers

- Products with high durability and corrosion-resistant

- Components that endure high temperature and external environmental changes.

Auto Component Specification

Materials

Dimensions

Surface Finish

Tolerance

Application

1. Precision Engineering: Auto components are crafted with precision and attention to detail, meeting strict quality control standards to ensure reliability and safety.

2. Durability and Longevity: These components are designed to withstand the rigors of everyday use and harsh environmental conditions, providing long-lasting performance.

3. Material Selection: High-quality materials, such as steel, aluminum, and various alloys, are used to manufacture auto components, ensuring strength and resistance to wear and corrosion.

4. Customization Options: Auto components are available in a wide range of sizes and configurations, allowing for customization to meet the specific requirements of different vehicles and applications.

5. Compliance with Industry Standards: Auto components adhere to industry-specific standards and regulations to ensure compatibility and safety.

Auto Component Uses in Industries

Marine Industry

Industrial Machinery

Specialty Vehicles

Our Other Products

Handles

Honed Tubes

Machinery Shaft

Hydraulic Shaft

Piston Shaft

Flanges

Shaft I Pins

Industrial Studs

Latest Blogs

A Breakdown Of Pump Impeller Types And Applications Impeller pumps

A Guide To Choosing A Hydraulic Shaft Manufacturer Hydraulic systems