Connectors Manufacturer In India

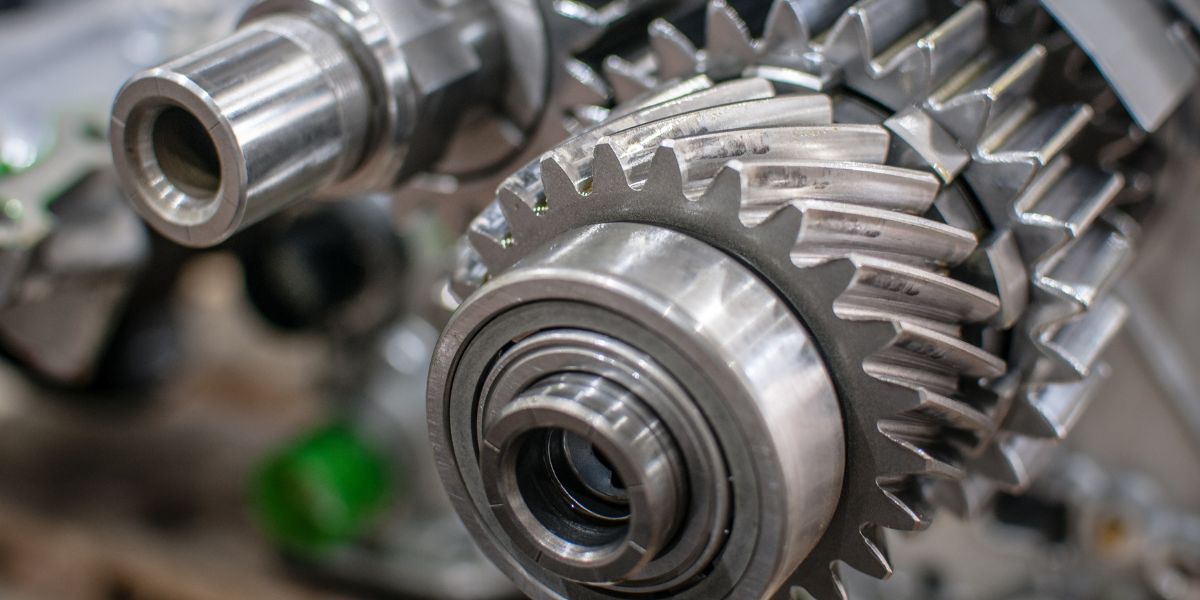

Crafted with meticulous precision and engineered to perfection, our connectors stand as a testament to our unwavering commitment to excellence.

Connectors Manufacturer At A Glance

- Connectors can be customized as per the unique needs of customers.

- We ensure a quality product manufactured from our resources.

- Production using advanced material science and technology.

- High durability and temperature-resistant connectors.

- Shipping nationwide

Connectors Specification

Materials

Stainless steel, aluminum, brass, or engineered plastics selected for durability and corrosion resistance.

Tolerance

Precision machining with tight tolerance control (+/- 0.001 to +/- 0.005 inches) ensures accurate fitment.

Surface Finish

Smooth finish achieved through machining, polishing, anodizing, or coating as needed.

Thread Type

Standard or custom threads for secure fastening and connectivity.

Geometry

Customizable shapes, sizes, angles, and configurations for optimal performance.

Connector Type

Available in electrical, fluid, or hybrid configurations for various application demands.

- Precision Engineering: Our connectors are crafted with advanced CNC machining, ensuring exceptional dimensional accuracy and repeatability for reliable connections crucial to uninterrupted operations.

- Customization Options: With CNC machining capabilities, we offer tailored solutions to meet specific industry needs, accommodating diverse specifications such as custom geometries, thread types, or surface finishes.

- Tight Tolerances: Adhering to strict tolerance standards, our machining process ensures precise mating interfaces and compatibility with industry-standard components, minimizing errors and enhancing system integrity.

- Wide Application Spectrum: From aerospace to automotive, telecommunications to medical devices, our connectors find utility across diverse industries, facilitating seamless connectivity for signal transmission and fluid handling in critical systems.

- Quality Assurance: Each connector undergoes rigorous quality control measures including dimensional inspection, surface finish assessment, and functionality testing, ensuring compliance with or exceeding industry standards for reliability and performance.

- Cost-Effective Solutions: Despite high precision and quality, our CNC machined connectors offer cost-effective alternatives to traditional manufacturing, thanks to optimized production processes and minimal material waste, delivering value without compromising quality.

Connectors Use In Industries

Aerospace

Telecommunications

Automotive

Electronic

Medical Devices

Our Other Products

Handles

Honed Tubes

Machinery Shaft

Hydraulic Shaft

Piston Shaft

Flanges

Auto Components

Industrial Studs

Latest Blogs

A Breakdown Of Pump Impeller Types And Applications Impeller pumps

A Guide To Choosing A Hydraulic Shaft Manufacturer Hydraulic systems