Crankshaft Manufacturer In India

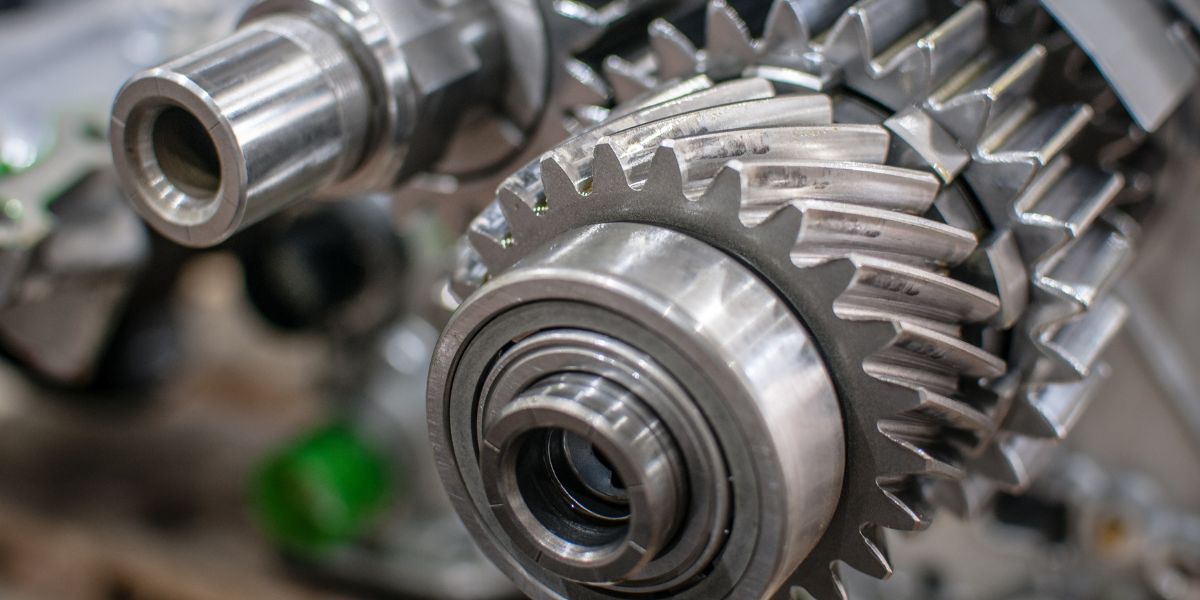

The most trustworthy crankshaft manufacturer in India is Bhansali Techno Component. We produce customizable crankshafts in different sizes and materials for various industrial purposes.

As a leading crankshaft manufacturing company, we specialise in custom crankshaft manufacturing to improve engine performance and prolong machine lifespan.

About Our Crankshaft Manufacturing

At Bhansali Techno Components, we prioritise delivering crankshafts of topmost quality. We have several years of experience in the industry as an auto components manufacturer and follow a rigorous quality-testing method to ensure each unit of crankshaft delivered offers maximum performance and satisfaction. We use high-grade raw materials and appropriate heat-treating methods to ensure our crankshafts can handle high load and stress conditions without disrupting engine operations. Our various customizable design options make our crankshafts ideal for different industrial applications.

We use the latest technology and equipment for the crankshaft manufacturing process. As a leading crankshaft manufacturer in India, we use ideal manufacturing methods, like forging, machining, and casting, to ensure each unit is reliable, durable, and suitable for dynamic applications.

- Customisable design and shapes for unique industrial requirements

- High-quality raw materials and advanced manufacturing process

- Superior quality maintenance with rigorous testing methods

- Products with durability and corrosion resistance assured

- Automotive precision components supplied across the country

Crankshaft Specifications

Material Grade

Carbon Steel: AISI 4130

Cast Iron: GG25 (EN-GJL-250) and GGG40 (EN-GJS-400)

Forged Steel: SAE 4340 and SAE 5160

High-performance alloys, including nickel and chromium.

Size/Diameter

40mm to 150mm

Length Single Piece Length

600mm to 1500mm

Tolerance

±0.01 mm to ±0.05 mm

Thickness

10 mm to 50 mm

Heat and surface treatment methods used

Quenching, tempering, and nitriding.

1. High-Quality Material: Crankshafts are manufactured with high-quality raw materials that ensure hardness, longevity, and resistance.

2. High Precision: We employ advanced manufacturing techniques for high precision and efficient operations.

3. Exceptional Durability: The top-quality materials used for manufacturing contribute to the durability of crankshafts, making them last for years without disruptions.

4. Smooth Surface Finish: The smooth surface finish ensures less friction, wear and tear, and maximum operational efficiency.

5. Highly Versatile: Through precision machining, we offer various customization options and ensure the crankshafts are suitable for different industrial applications.

Crankshaft Applications Across Industries

We’re glad to contribute to the operations of major industries in India and abroad while building a strong presence in manufacturing.

Automotive and Aerospace Industries

Construction Machinery

Hydraulic and Pneumatic Applications

Manufacturing and Industrial Machinery

Material Handling Equipment

Printing and Packaging

Our Other Products

Honed Tubes

Pump Shaft

Machinery Shaft

Hydraulic Shaft

Piston Shaft

Flanges

Auto Components

Industrial Studs

Latest Blogs

A Breakdown Of Pump Impeller Types And Applications Impeller pumps

A Guide To Choosing A Hydraulic Shaft Manufacturer Hydraulic systems