Heat Exchanger Manufacturer In India

Bhansali Techno Components are a leading heat exchanger manufacturer in India and maintain uncompromising quality with each part of a heat exchanger delivered to ensure utmost durability, performance, and safety.

Bhansali Techno Components is your top choice for your company’s needs for high-quality heat exchanger parts. We follow rigorous safety and quality maintenance methods to ensure our precision parts meet your high expectations and unique requirements.

About Our Heat Exchanger Parts

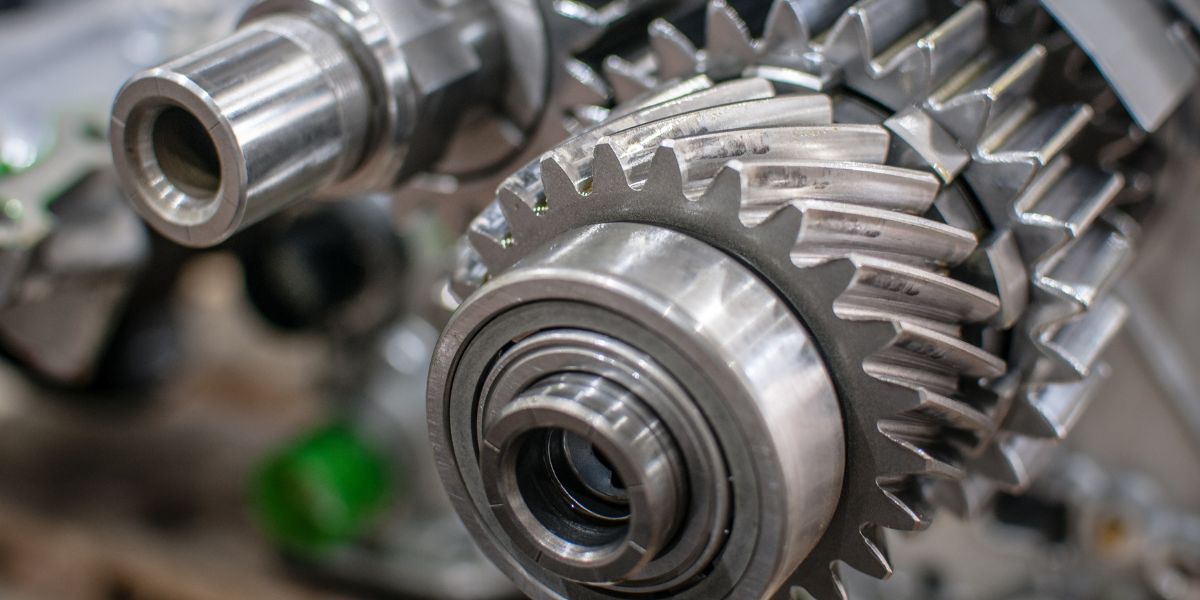

At Bhansali Techno Components, we bring together technology, innovation, and years of experience to manufacture high-quality heat exchanger parts. Our team comprises highly skilled professionals with diverse experience in manufacturing and quality maintenance. We use the latest precision engineering and fabrication techniques to manufacture durable parts and meet the expectations of the demanding industrial environments. We aim to gain global recognition as the leading heat exchanger manufacturer and supply superior-quality precision parts to more booming industries.

Our advanced manufacturing methods enable us to cater to the unique requirements of different industries. We personalize our heat exchanger parts based on industrial requirements and ensure they contribute to the operational excellence of powerful machines and engines.

- High-quality raw materials used in manufacturing

- Advanced technology and material science combined for the best results

- Customizable heat exchanger parts according to industrial use and requirements

- Competitive and transparent pricing

- Precision parts supplied to various industries across the country

Heat Exchangers Specification

Material Grade

Steel (AISI 1020), Carbon Steel (ASTM A516), Copper alloys, and Cast Aluminium Alloy (A356)

Application

Various industrial applications, including:

- Power Generation: Tubes and baffles used in boilers and condensing systems.

- Chemical Industry: Coils and gaskets used in reactors and plate heat exchangers.

- Food and Beverage: Plates and seals for pressurized production.

Tolerance

Depending on the parts chosen.

Surface Finish

Proper machining technique used for smooth surface finishing and reduced friction.

1. High-grade Raw Materials: Our priority is choosing raw materials of topmost quality when manufacturing heat exchanger parts. Top materials also ensure more durability, longevity, and corrosion resistance.

2. Corrosion Resistance: We use proper manufacturing techniques and heat-treating methods to make all parts corrosion-resistant.

3. Durability: The use of high-quality stainless steel, copper steel, copper, and aluminum alloys adds to the durability of each part.

4. Highest Precision: Our advanced manufacturing technology enables accurate dimensions, shapes, and finishings, leading to high precision.

Heat Exchanger Use in Industries

We are proud to be a trusted partner to leading industries in India across chemical, oil and refining, pharmaceuticals, food and beverages, nuclear and energy, dairy, automobile, power generation, and more.

Automotive and Aerospace Industries

Construction Machinery

Hydraulic and Pneumatic Applications

Manufacturing and Industrial Machinery

Material Handling Equipment

Printing and Packaging

Our Other Products

Honed Tubes

Pump Shaft

Machinery Shaft

Hydraulic Shaft

Piston Shaft

Flanges

Auto Components

Industrial Studs

Latest Blogs

A Breakdown Of Pump Impeller Types And Applications Impeller pumps

A Guide To Choosing A Hydraulic Shaft Manufacturer Hydraulic systems