Why Honed Tubes Standard Size Are Matters?

Taking a closer look at the manufacturing process of hydraulic cylinders for multiple industrial and mechanical purposes, the role of honed tubes is undeniable. Often also recognized as ‘cylinder tubes,’ honed tube standard sizes have several variants with different inner and outer diameters manufactured to fit hydraulic cylinders of various sizes.

It is not just manufacturing; honed tubes are equally essential in repairing pneumatic and hydraulic cylinders. These tubes are implemented into cylinders to boost their functionalities, quality, and safety. Therefore, this is a vital reason why buying high-quality honed tubes and choosing a reliable precision component manufacturer is so important.

A Quick Overview Of Honed Tube Standard Sizes

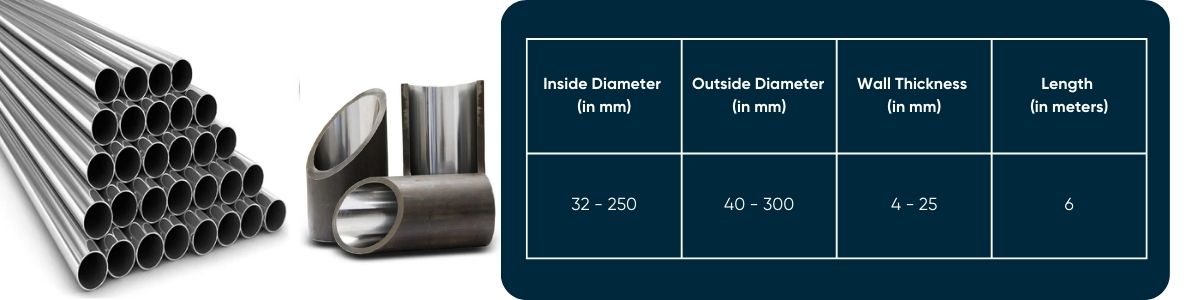

There is a large variation of honed tube standard sizes, starting from 32 mm to 800 mm. Honed tubes are highly customizable; therefore manufacturers cut the length of the tubes as per the industrial requirements. Here is a detailed table of the metric sizes of standard honed tubes that most of the leading honed tube manufacturer in India prefer.

| Inside Diameter (in mm) | Outside Diameter (in mm) | Wall Thickness (in mm) | Length (in meters) |

|---|---|---|---|

| 32 | 40 | 4 | 6 |

| 35 | 45 | 5 | 6 |

| 40 | 50 | 5 | 6 |

| 50 | 60 | 5 | 6 |

| 55 | 65 | 5 | 6 |

| 60 | 70, 75, 80 | 5, 7.5, 10 | 6 |

| 63 | 75, 78 | 6, 7.5 | 6 |

| 70 | 80, 85, 90 | 5, 7.5, 10 | 6 |

| 75 | 90, 95 | 7.5, 10 | 6 |

| 80 | 90, 95, 100 | 5, 7.5, 10 | 6 |

| 85 | 100 | 7.5 | 6 |

| 90 | 105 | 7.5 | 6 |

| 100 | 115, 120, 125 | 7.5, 10, 12.5 | 6 |

| 110 | 125, 130 | 7.5, 10 | 6 |

| 115 | 130 | 7.5 | 6 |

| 120 | 140, 145, 150 | 10, 12.5, 15 | 6 |

| 125 | 145,150 | 10, 12.5 | 6 |

| 130 | 150 | 10 | 6 |

| 140 | 160, 165, 170 | 10, 12.5, 15 | 6 |

| 145 | 170, 175 | 12.5, 15 | 6 |

| 150 | 170, 180 | 10, 15 | 6 |

| 160 | 180, 185, 190, 200 | 10, 12.5, 15, 20 | 6 |

| 180 | 200, 210, 220 | 10, 15, 20 | 6 |

| 200 | 220, 230, 245 | 10, 15, 22.5 | 6 |

| 250 | 300 | 25 | 6 |

Need For Honed Tubes Across Industries In Various Sizes

The application of honed tubes is vast; numerous industries use them in manufacturing processes to deliver top-notch products to their customers. This is also why honed tubes are always in the highest demand in industries such as aerospace, automotive, machinery, construction, mining, and pneumatic and hydraulic systems.

Honed tubes are known to positively impact the efficiency, performance, and reliability of hydraulic systems, and they have experienced the highest global demands recently. Manufacturing industries are adapting computer-controlled honing machines and automated methods to meet the increasing demand for various honed tube sizes.

With technological advancements, like artificial intelligence (AI), controlling massive production and achieving the highest geometric accuracy in honed tube standard sizes has become much easier. Manufacturers also rely on advanced technologies to boost the intricate honing processes and align with different industrial needs for honed tubes.

Factors To Consider When Selecting Honed Tube Sizes From Manufacturers?

With so many size options, picking the appropriate honed tube sizes might be your most difficult decision. To make it easier, here are some crucial factors you must consider when deciding the size of honed tubes for your industrial requirements.

1. Application Requirements

Selecting the right honed tube sizes is most appropriate when you have an in-depth understanding of the application requirement, such as for what purpose you seek honed tubes and how they will impact your operational environment. You must also not forget about the factors that impact your industrial activities, like temperature, pressure, and load conditions, which are very crucial when choosing the sizes of honed tubes.

2. Material Composition Of The Tubes

Honed tubes are built to endure tough industrial conditions, but their material composition is of the greatest concern when selecting the size as the dimensions, accuracy, and finishing vary with the materials chosen for manufacturing.

Usually, honed tubes are manufactured in stainless steel, carbon steel, non-ferrous metals, or alloy steel. Each of these materials significantly impacts the machinability, structure and finishing, corrosion, and durability while cutting them into desired shapes and sizes for industrial use.

3. Customization Flexibility

Sometimes, additional customization is required to align honed tube sizes with specific industrial requirements. Therefore, manufacturers add special features to ensure each size of the honed tube fits perfectly with your hydraulic systems. A reliable manufacturer allows you to customize vital features like plating, coating, geometrics, etc.

4. Honing Method Used

The method chosen by a manufacturer for honing tubes is of great concern. Usually, manufacturers use two honing methods, rotary and planetary, to obtain desired sizes, but the major difference can be seen in the finishings.

If you are seeking honed tubes with polish and smooth finish, you must choose the products of rotary honing. In contrast, planetary-honed tubes are a perfect choice if you are looking for honed tubes with rough finishing. You must also note that the pricing of honed tube sizes will also depend on the chosen honing method.

5. Tolerance and Surface Finish

Honed tubes are praised for accuracy; therefore, dimensional tolerance is important when choosing honed tube sizes. You must focus on honed tubes with better surface finish and dimension as it helps reduce wear and tear caused by friction. With better surface finishing and dimensional tolerance, you can expect higher compatibility.

Refer Reliable Manufacturer For the Honed Tube Sizes

India has a large number of honed tube manufacturers, and finding the most reliable one can be challenging. To simplify your search process, Bhansali Techno Components offers superior-quality precision components built to last.

From guidance on choosing the right honed tube size for your business to customized or specialized features, Bhansali Techno Components is there to help you in every aspect. You can also enquire about the honed tube kg price and every other concern you have, as we are here to solve all your queries and deliver mechanical components meeting the highest quality standards and your business expectations.