Honed Tubes Manufacturers In India

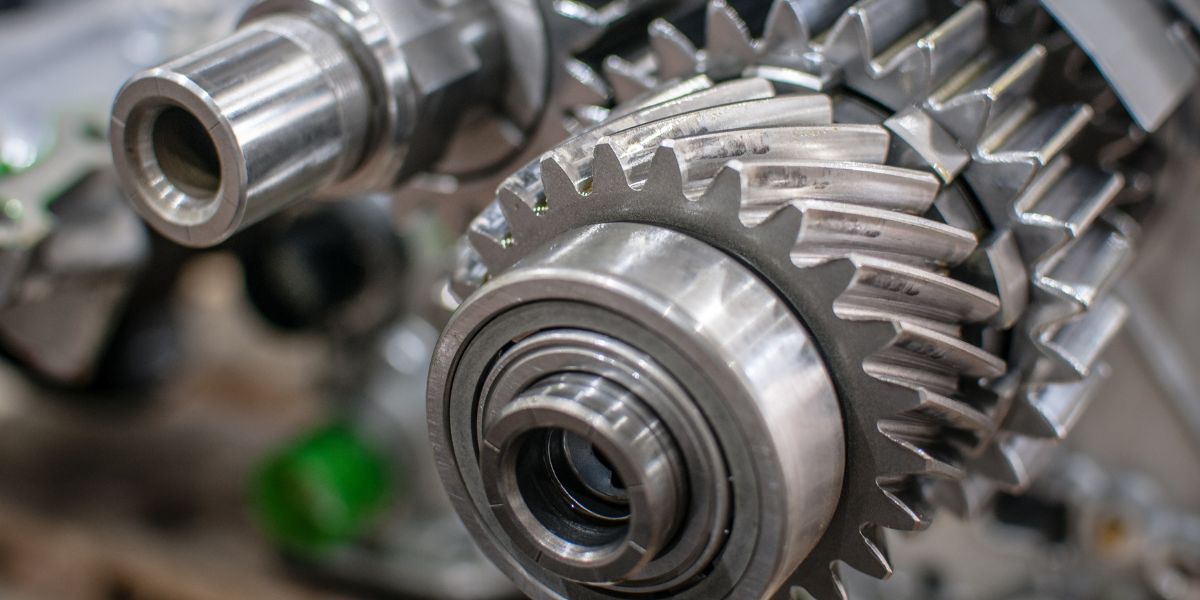

Our honed tubes feature a smooth interior surface, meticulously crafted using cutting-edge technology to deliver superior performance and reliability.

Honed Tubes At The Best Prices In India

- Honed Tubes can be produced according to customers’ specific designs.

- We ensure a quality product manufactured from our resources.

- Production using advanced material science and technology.

- High durability and temperature-resistant connectors.

- Shipping nationwide

Honed Tubes Specification

Material Grade

Unit Pipe Length

Material

Bore diameter

Internal Diameter Accuracy

Internal Roughness

1. High-Quality Inner Surface Finish: The honing process results in a mirror-like inner surface finish with fine micro-finish values. This ensures reduced friction, wear, and minimal fluid leakage in applications where precision matters.

2. Tight Tolerances: Honed tubes are manufactured to stringent dimensional tolerances, providing uniformity and precision in critical dimensions, making them ideal for piston applications.

3. Customizable Specifications: Available in various sizes, materials, and tolerances, honed tubes can be tailored to meet specific project requirements and application needs.

4. Corrosion Resistance: Depending on the material used, honed tubes can offer excellent resistance to corrosion, making them suitable for use in corrosive environments.

5. Strength and Durability: Honed tubes are designed to withstand high-pressure hydraulic and pneumatic applications, making them reliable and long-lasting components.

Honed Tubes Use in Industries

Aerospace

Automotive Industry

Food and Beverage Processing

Hydraulic and Pneumatic Systems

Medical Devices

Oil and Gas

Precision Machinery

Our Other Products

Handles

Pump Shaft

Machinery Shaft

Hydraulic Shaft

Piston Shaft

Flanges

Auto Components

Industrial Studs

Latest Blogs

A Breakdown Of Pump Impeller Types And Applications Impeller pumps

A Guide To Choosing A Hydraulic Shaft Manufacturer Hydraulic systems