Digging Into The Uses And Industrial Applications Of The Honing Process

The honing process refers to a precision technique revolving around the machines. It helps to maximize the output by enhancing the machine’s function to achieve exceptional levels regarding the surface process, along with promising proper geometry, dimensional accuracy, and precision. It is not specific to one but offers a versatile use for various mechanical components.

Honing machines are in great demand. They are metal abrading tools and process the utilization of complex tools, along with perishable abrasive stones. The idea is to correct the use of the following:

- The diameter of the byproduct

- Shape

- Surface finish

- Positional tolerances of bores

So, if you are wondering whether your industrial unit will benefit from this process or not, here is an overview of the process, its uses, advantages, and the different industries that benefit from it.

What Is Honing Process In Manufacturers?

The honing process is used to ensure that machine parts perform their best and deliver what is needed with the best quality and the least re-dos or input costs. But everything comes down to choosing the right firm for your industrial needs. Bhansali Techno Components is a trusted name, and you can reach out to them for different machine use cases and applications for quality assurance and experienced input.

The idea behind developing the honing process in manufacturers is to promise perfection in bore geometry, size control, surface finish, and structuring before presenting the final look. The process helps in final sizing and plays a significant role in creating the desired finish pattern of the tubing interiors or the cylinder bores. It is different from lapping. Lapping means sanding or polishing methods that help to create an accurate finish on the flat surface of the machine’s part. Honing is an internal grind.

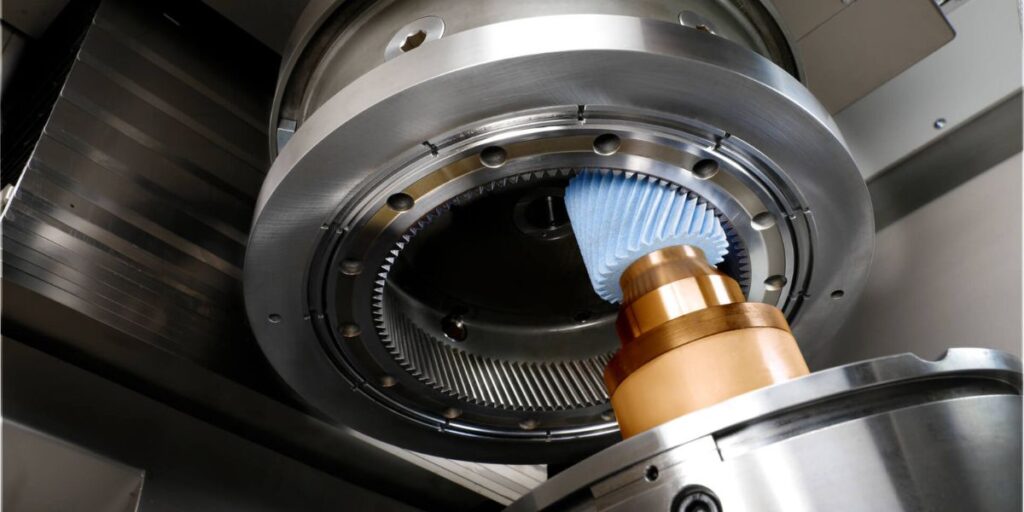

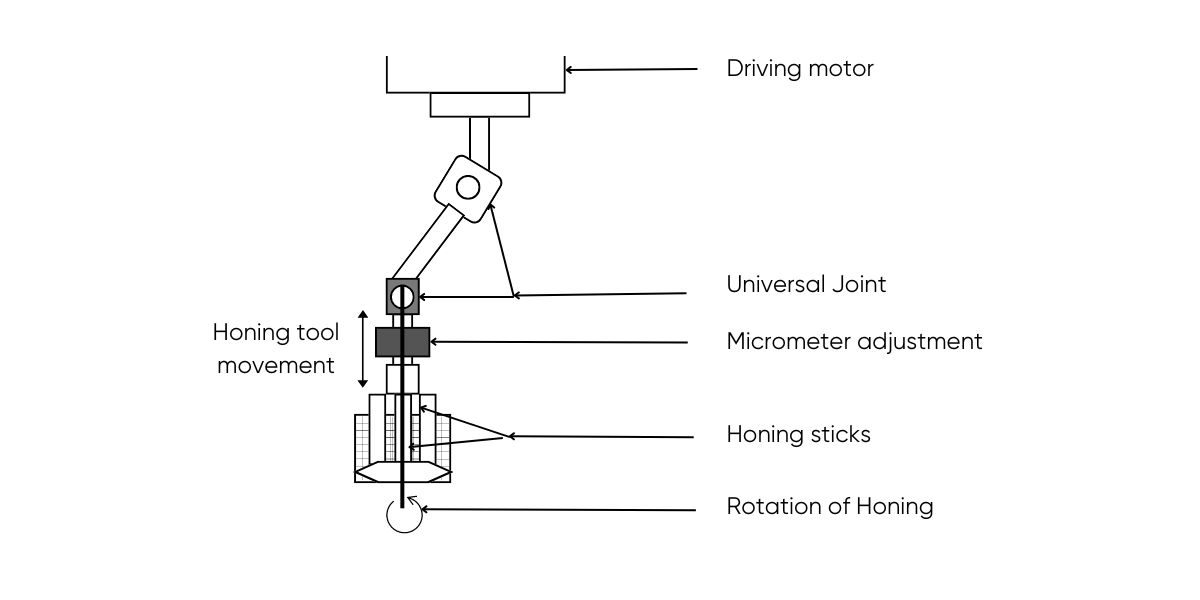

The product’s finishing is accomplished by expanding the abrasive stones, which ensure a suitable grit and grade against any of the work surfaces where it is placed. The stones are in a rotation mode, and they reciprocate in part with the honing abrasive. This reliable function occurs during controlled pressure. When the rotation and reciprocation processes are combined, they help produce a cross-hatch pattern on the surface, specifically where the honing occurs.

Use Of Honing In Machine Parts

The precision components manufacturers in India prefer this process over others because of its cost-effectiveness. The cost-effectiveness is not related to one sub-part but in totality, including the following:

- Removing stock above the requirements

- Generating exciting

- Bore tolerances and polishing

- Finishing bores of different materials, including sprayed coatings, ceramics, and others like CGI

The process involves functional benefits like the following:

- Better final product quality

- Improved accuracy

- Faster results

- Efficient production

- No human involvement

- Precise finish

- Cost-effective

The Honing Process Steps

The honing machine process helps you get the final sizing of the product included with the desired finish pattern, especially on the interiors of parts like tubing or cylinder bores. The manufacturers should ensure that the process follows the three proper steps.

- The first step includes the stock removal process, which helps remove the ruptured metal and reach the machine’s base metal.

- After the step has been qualitatively achieved, it is essential to focus on the achievable finishing patterns.

- The finishing pattern is generated to provide the best surface for qualitative outputs in the future.

Also, generating it helps promote optimum lubricating conditions so there are no issues in the final stage. The whole idea of bringing this concept into practice is that you are assured of the surface’s straightness. The honing process helps ensure the proper roundness and size of the surface, too.

Application Of Honing Process In Other Industries

Manufacturers often wonder, what is the honing process used for apart from the machine use? Well, honing machines are not confined to the manufacturing industry. There are different kinds of honing machines available, such as manual and machine, and hence, their use is extended to different industries. You will be surprised to know some of the use cases of the honing machinery process. Here are some reliable industrial use cases of the same.

Medical

Precision is non-negotiable in the medical field. Tight tolerance is the need of the hour, and superior surface finishes help ensure safe procedures. The manufactured components, with the help of the honing process, help deliver reliable medical components that are highly demanded in treatments like joint pain and replacements.

Aerospace And Defense

Precision engineering and this sector run parallel. The industry needs accurate specifications, tight tolerances, and incredible finishes to maintain the robust nature of finished products. The process ensures the market requirements of meeting the safety standards.

Printing And Packaging

Precision rollers and shafts are commonly used in the conversion, printing, and packaging industries. This is not a new practice; it has been in the game for years. The industry needs reliable components that offer a perfect balance and surface finish. That’s when the honing process emerges and delivers the expected.

Hydraulics And Petrochemicals

The hydraulics and petrochemicals industry also sees the honing process as essential for producing surface finishes that offer work effectiveness and no excessive wear and tear. The manufacturers ensure that the machinery is provided at cost-effective prices, and if you need more time, do some market research to get your hands on the best.

Automotive Industry

There is a chance that the honing steps are confused with lapping or grinding. The honing process helps create an optimum finish for different kinds of auto components, including brake drums and engine blocks. These parts help drive the shafts and anti-roll bars. The honing process is perfect for eliminating the imperfections that meet the eye on metal surfaces. It also helps to achieve precise geometric tolerances.

Honing: The Reliable Step For A Quality Product

The honing process is reliable for qualitative finished products. Its use is not limited to the manufacturing sector, as the process’s basic deliverables will likely benefit more than a single industry. However, for the desired output, you must ensure that an experienced team of professionals conducts the process.