A Helpful Guide To Choosing Between Horizontal And Vertical Millings

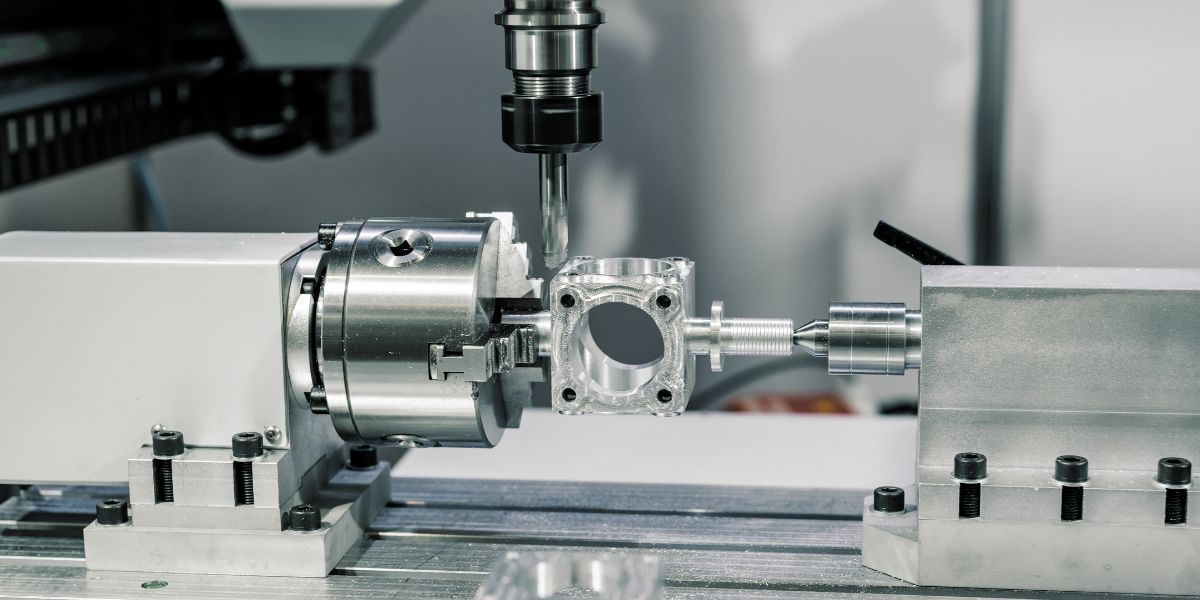

Commonly used in manufacturing processes, horizontal vs vertical mill machines are versatile tools capable of creating parts that require a variety of designs, drills, grooves, and more. Milling machines use a rotating cutting tool to remove material from stationary workpieces and give them the desired shapes and cuts.

Horizontal or vertical, the choice of a milling machine depends on the specific cuts and shapes required for the manufacturing product. While both types serve a similar purpose, horizontal mills excel at cutting deeper and heavier grooves, while vertical mills are the go-to for intricate designs and shapes.

Read this detailed guide to decide which type of milling is best for your manufacturing needs.

What Are The Differences Between Horizontal And Vertical Milling Machines?

There is a lot of difference between a horizontal vs vertical mill, even if they are used for similar functions (cutting and shaping). Let’s explore their primary differences in detail, from their applications to their setup and capabilities.

| Features | Horizontal Milling | Vertical Milling |

|---|---|---|

| Spindle Orientation | The spindle is horizontal and is parallel to the worktable. | The spindle is vertical and perpendicular to the worktable. |

| Purpose | They are used for deeper cuts, grooves, slots, and other heavy-duty contour tasks that are more complex. | Used for simpler vertical drilling, cutting, and shaping tasks. |

| Positioning of the Workpiece | Horizontal mills sit on the table that is parallel to the spindle. | Vertical mills sit on the table and are perpendicular to the spindle. |

| Feed Control | Controlled either automatically or manually. | Usually controlled manually. |

| Versatility | As horizontal millings have a complex design and setup, they are less versatile and are ideal for only specific types of operations. | These millings are highly versatile and used in different cutting operations. |

| Types of Cutting Tools | Different cutting tools are used in horizontal milling, including face and slab mills. | Usually works with face and end mills. |

| Ease of Tooling Setup | Tooling setup in horizontal millings is a complex process because it has a horizontal arbor. | This milling type requires a simple tooling setup as it has a simple design. |

| Tool Life | Longer tool life because of its effective cooling and chip evacuation. | Shorter tool life. |

| Accessibility | It is easy to access the workpieces from every angle. | Offers limited accessibility, especially when it comes to handling large workpieces. |

| Compatibility with Automation | Easily compatible with automation, and hence are suitable for mass production. | It is incompatible with automation and requires more manual operations to perform tasks. |

| Cost | The cost of these millings is usually high because of their complexity and size. | These millings are much cheaper and are available in smaller, more affordable models. |

| Maintenance | It requires more maintenance because of the complexity of design, operations, and heavy workload management. | It requires low maintenance and consists of a simple design. |

| Production Volume | Suitable for high-volume production | Suitable for low-volume production |

| Flexibility | Less flexible as these millings have a complex setup and are not open to changes. | Very flexible, it is easy to change the setup of these millings according to the task’s requirements. |

| Material Removal Rate | Offers a higher material removal rate and is suitable for heavy cutting requirements. | Provides a lower material removal rate and is ideal for precision requirements. |

| Skills Required | Working with horizontal milling requires a higher level of skills because of the complexity of setup and operations. | Ideal for all skill levels, even beginners can efficiently operate vertical milling. |

Benefits Of Using Horizontal And Vertical Millings

Milling machines are frequently used in metal fabrication industries. A vertical mill vs a horizontal mill is attached to the manufacturing machines to obtain desired cuts and shapes. There are different types of milling machines, and each has its perks, so making the right decision is essential.

Horizontal Millings

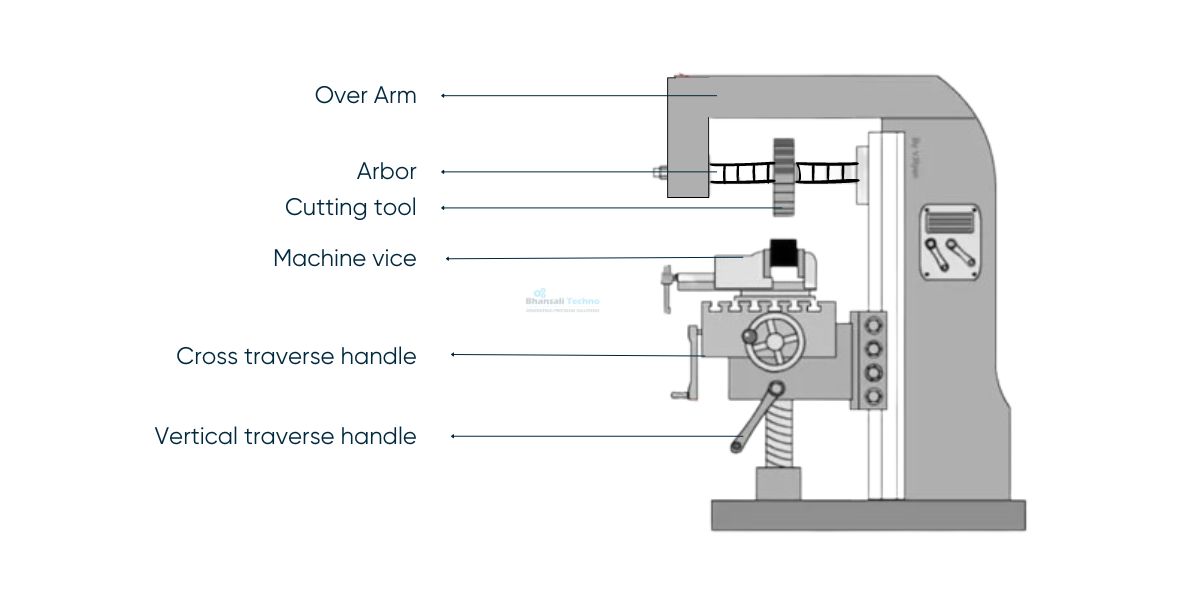

Suitable for heavy requirements, horizontal millings include a horizontally attached spindle parallel to the workstation. The spinning motor of the spindle consists of a cutting tool that makes cuts, holes, designs, and other horizontal detailing on the manufacturing parts. Horizontal millings are most appropriate when there is less requirement for accuracy but deeper grooves and cuts on thicker materials.

Comparing horizontal vs vertical mill accuracy, horizontal millings perform their duties faster than vertical, and the final results are smoother. As the setup is horizontal, gravity works wonders on these milling machines, making pulling chips out of materials easier. The other benefits of horizontal milling are:

- Precise finishings

- Ideal for heavy materials

- Requires shorter processing time

- Has larger capacity

- Less risk of damage

- Can make deep cuts and grooves smoothly

- The ultimate milled materials require less fabrication

- Less wastage of material

Vertical Millings

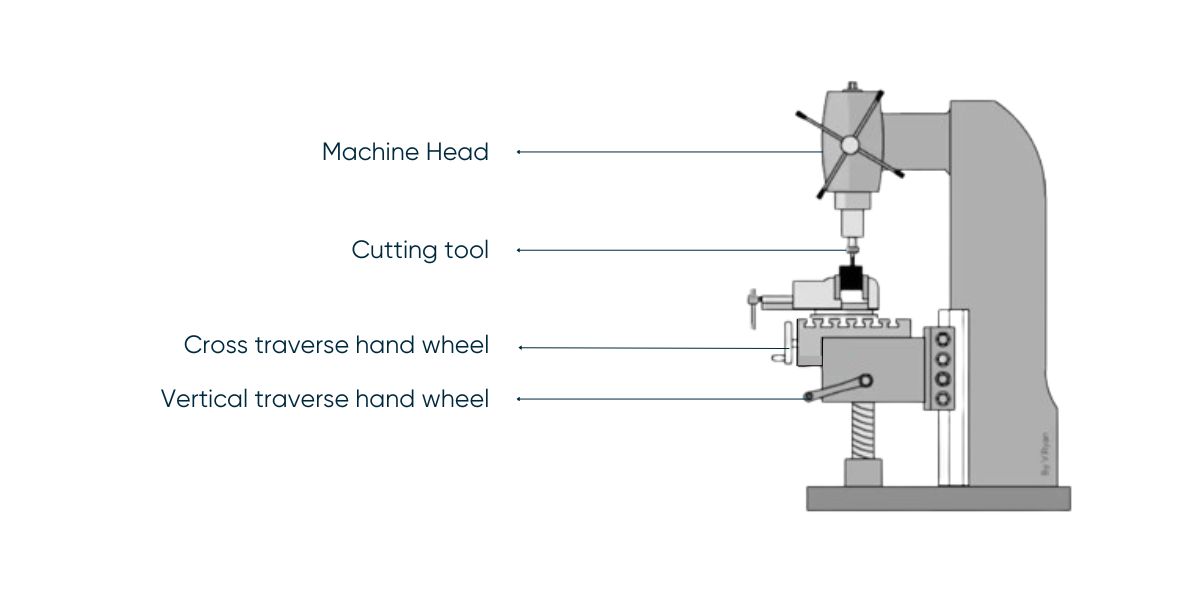

Easy to adjust and maneuver, vertical milling has a vertically attached spindle parallel to the workstation. These millings are essential for precision and making cuts and designs on solid materials. Vertical millings require manual movements to support their cutting and shaping processes and are popularly used in cutting and shaping metals, wood, plastics, and any other solid material.

Vertical millings are frequently used in industrial manufacturing because of their high functionality. They help transform raw materials into intricate parts or shape and cut materials into their desired forms. Some other incredible benefits of vertical milling are:

- Higher accuracy compared to horizontal millings

- Versatile and can be used on different materials

- Requires low maintenance

- Easy to operate and monitor

- Higher precision

- Easy to adjust

Purchasing Horizontal And Vertical Millings From Trustworthy Manufacturers

Your decision to purchase high-quality horizontal and vertical millings directly impacts your manufacturing processes and overall operations. This is why choosing a reliable precision component manufacturer who never compromises quality and delivers durable and tested components is crucial.

At Bhansali Techno Components, you can expect manufacturing components that meet the highest quality standards and are passed through rigorous testing. These standard mechanical components ensure your manufacturing processes run smoothly, and you can achieve more accuracy and efficiency in operations. A reliable manufacturer also guarantees the millings of your choice are durable and versatile and ideal for small or large-scale precision prototyping tasks.