A Guide To Choosing A Hydraulic Shaft Manufacturer

Hydraulic systems are important in many industries, like construction, automotive, and aerospace. At the heart of this system is the hydraulic shaft. It transfers force and motion.

Choosing the right hydraulic shaft manufacturer is a vital step. It affects many things. First, how your equipment works. Secondly, how long it lasts. And finally, how efficient your equipment is.

A good manufacturer can improve system durability and reduce downtime. We will cover the essential things to consider when choosing a shaft manufacturer in this blog. We will also focus on hydraulic shaft production in India. So you can make an informed decision.

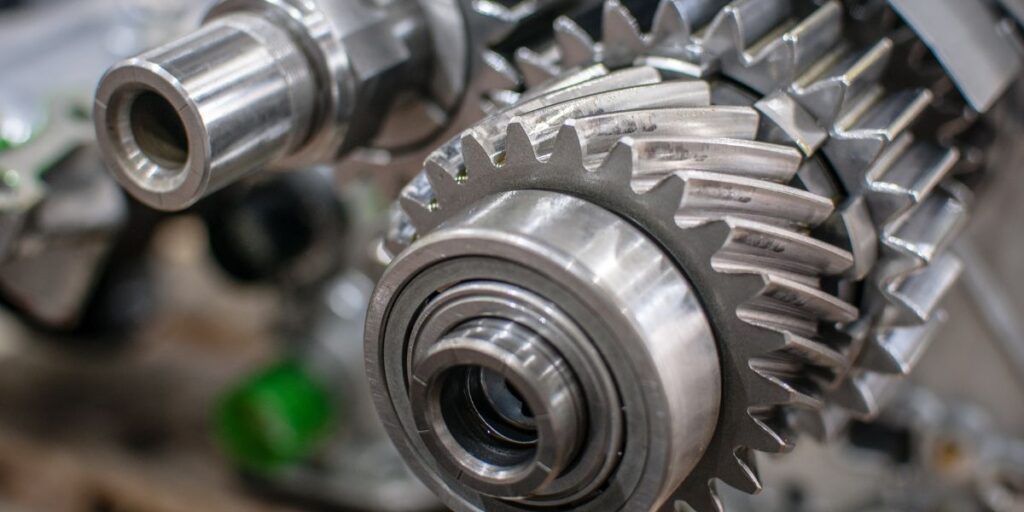

Understanding Hydraulic Shaft

Hydraulic shafts are essential parts of hydraulic systems. They help transfer power. And make sure to move different parts of the machinery smoothly and efficiently. These shafts are made to handle high pressure and torque. This makes them essential in many industries. The same goes for precision component manufacturers. Hydraulic shafts are used in heavy machinery and factory equipment. They help things run smoothly. You’ll also find them in renewable energy systems like wind turbines. They keep everything moving efficiently.

There are different types of hydraulic shafts for various tasks –

- Rotary Shafts: Transmit rotational force in pumps and motors.

- Linear Shafts: Convert hydraulic pressure into straight-line motion.

- Precision Shafts: Make for tasks that need high accuracy and minimal tolerance.

Top Reasons To Pick The Right Hydraulic Shaft Manufacturer

Selecting a good shaft manufacturer is essential for your hydraulic system. The right choice can affect how well your equipment works. Here are some key factors to look at:

1. Quality And Standards

Quality is the top priority when selecting a hydraulic shaft producer. High-quality shafts perform well under pressure. Here are the essential points to consider.

Certifications

You should look for manufacturers with important certifications. Here are the examples.

- ISO 9001 – Makes sure a structured and top-quality management system.

- ASME and DIN – Industry standards for safety and efficiency.

Quality Testing

A good manufacturer conducts rigorous testing during and after production. This guarantees that each hydraulic shaft is reliable and effective.

| Reason | Importance |

|---|---|

| Certifications | Confirms quality management |

| Industry Standards | Ensures safety and efficiency |

| Testing Procedures | Validates reliability of products |

2. Experience And Reputation

Experience matters in the hydraulic shaft industry. A manufacturer with a solid track record will understand your needs better. Here is what you need to find:

Research Reputation

Check customer testimonials and reviews. Positive feedback indicates a trustworthy manufacturer.

Track Record

Choose companies with years of experience. Long-standing manufacturers are more likely to provide reliable service.

| Reason | Description |

|---|---|

| Customer Feedback | Indicates reliability and performance |

| Industry Longevity | Shows depth of experience and expertise |

3. Customization And Technical Support

Every industry has unique needs for hydraulic shafts. Customization can make a significant difference. Consider these aspects:

Customization Options

A good manufacturer offers:

- Adjustable dimensions

- Choice of materials

- Various finishes

Technical Support

Access to knowledgeable engineers can be very helpful. They can assist in selecting materials and optimizing designs.

| Feature | Importance |

|---|---|

| Adjustable Dimensions | Ensures perfect fit for your system |

| Material Choices | Tailor performance to specific needs |

| Expert Guidance | Saves time and improves product quality |

4. Material And Technology

The materials used in hydraulic shafts directly affect their performance and durability. Here’s what you should consider:

Material Selection

Common materials include:

- Stainless Steel: Resists corrosion and is ideal for wet environments.

- Alloy Steel: Offers high strength for heavy-duty applications.

- Carbon Steel: A cost-effective choice with good strength.

Advanced Technology

Look for manufacturers that use modern techniques like – CNC Machining: Ensures precision in production. Laser Cutting: Reduces defects and improves consistency.

| Material | Benefits | Best Use Cases |

|---|---|---|

| Stainless Steel | Corrosion resistance | Wet environments |

| Carbon Steel | Cost-effective | General purposes |

| Alloy Steel | High strength | Heavy-duty applications |

5. Pricing And Delivery Time

Cost and delivery time are critical factors when choosing a manufacturer. Here’s how to balance them.

Cost vs. Quality

Prices can vary. While lower hydraulic shaft prices are tempting, don’t sacrifice quality. A cheaper shaft may lead to failures and higher costs later.

Timely Delivery

Delays can hurt your productivity. Choose a manufacturer that provides clear and reliable delivery timelines. This ensures your project stays on schedule.

| Factor | Considerations |

|---|---|

| Cost | Balance affordability with quality |

| Delivery Timelines | Ensures punctual and reliable service |

Smart Tips For Choosing The Best Hydraulic Shaft Producer

These tips will make it easier to find the best fit for your project:

Request Quotes

Contact several manufacturers and request quotes. So you can compare prices and know the market rate.

Visit Facilities

If possible, tour the manufacturer’s facilities. Check their technology, production capabilities, and quality control processes.

Ask For Samples

Request product samples or case studies. Seeing the quality firsthand ensures the manufacturer meets your expectations.

Engage With Technical Staff

Speak with the technical team. Their knowledge and helpfulness show they care about your project’s success.

Check Lead Times

Ask about production and delivery timelines. Delays can affect your project, so ensure the manufacturer can meet your deadlines.

Review Customer Feedback

Look at testimonials or reviews from previous clients. Positive feedback indicates reliability and high-quality products.

Check Customization Options

Ensure the manufacturer can adjust designs and materials to fit your specific needs.

You’ll find the top hydraulic shaft manufacturing company in India that meets your project’s needs and timeline with these tips easily.

Find The Right Hydraulic Shaft Manufacturer

You have to get the right shaft manufacturer. It is the key to your system’s performance. Look for quality, experience, and customization options. It will help you find the best shaft manufacturer. Take the time to research, ask for quotes, and check customer feedback before booking. Talking to the technical team helps you see their skills and support. You can find one that fits your budget and delivers on time by checking out different manufacturers. Making the right choice helps your hydraulic system run better. So, you must connect with the Bhansali Techno Component. Call now to ensure long-term success for your projects.