Quality

Why Do You Need A Product?

Choose a product given

Incoming Inspections

Solutions

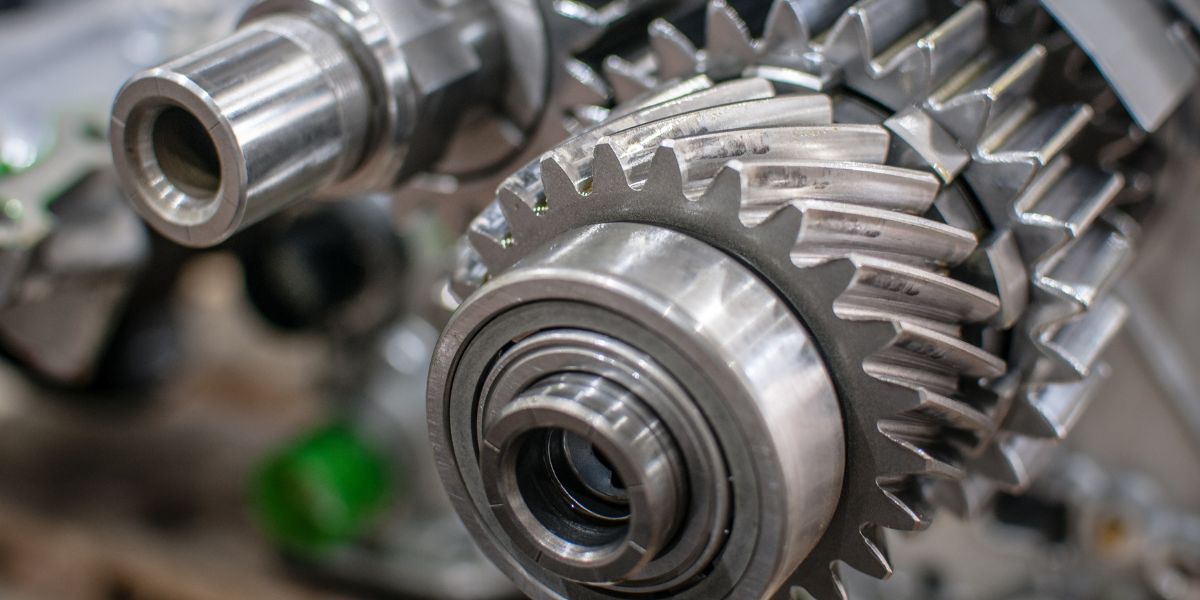

- In-process Inspection for quality checks at every production stage.

- Dimensional Accuracy of every product for precise dimensional specifications.

- Visual Inspection to check for external damages or cracks.

- Functional testing to understand performance rates.

Infrastructure

- Cutting-Edge Technology

Empowered with machinery like CNC turning centers, conventional lathes, bandsaws, etc., for high precision.

- Supply Chain Management

- Research and Development (R&D)

- Quality and Assurance

What We Do in Quality Inspections

Material Composition Analysis

Non-Destructive Testing (NDT)

Certification and Compliance

As precision components manufacturers in India, we have been certified with ISO 9001:2008. We are committed to quality assurance, established with excellent quality production and superior elements. With industry certification, we thoughtfully shape the specific management systems and requirements of manufacturing units. This supports a well-defined manufacturing process, enabling us to produce components within a controlled and consistent environment. We also meet regulatory needs for sustainable and safe products through compliance with industrial standards. Thus maintaining transparency and traceability of components.

Dimensional Accuracy

Metallurgical Analysis

Packing and Shipping Inspection

Manufacturing a superior quality product and keeping it safe throughout the transition is a task. Therefore, we use different steps of packaging and sealing to keep the product safe during transportation. The products undergo a secure seal first before the final packing. Following this, we have a visual inspection to check intact packaging and sealing. Our professional inspection team then verifies each package, including shopping details and accompanying documentation like invoices. We provide additional protective layering like anti-static packaging and temperature control for specific products

Milestones in Our Journeys

Certificate of Registration

Quality Policy

Latest Blogs

A Breakdown Of Pump Impeller Types And Applications Impeller pumps

A Guide To Choosing A Hydraulic Shaft Manufacturer Hydraulic systems