A Comprehensive Overview Of Industrial Fasteners

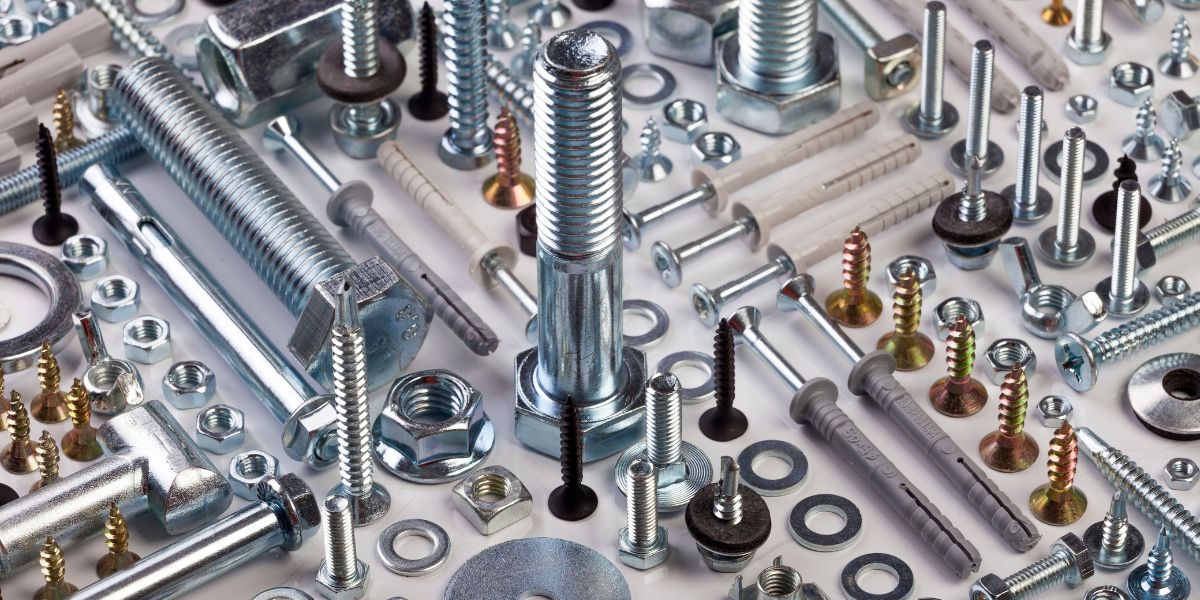

It would be difficult to imagine an industrial setting that does not require the permanent or non-permanent joining of various industrial components. A fastener helps in doing just that, it helps fasten or hold two or more objects/ parts together. There are several types of industrial fasteners, like bolts, U Bolts, rivets, screws, etc, that have varied applications in all sorts of industries.

Out of several fasteners available in the market, high-tension fasteners are the most popular and highly utilized fasteners. This is because these high-tension fasteners do not break or crumble under great pressure/mechanical stress. In short, the role of high-tension fasteners in industrial applications is immense, and no industry can function without them.

High Tensile Fasteners Roles

Fastener manufacturers sell different grades of fasteners, and they are classified into several grades based on the Mega Pascals of weight they can take. Most of the component manufacturers in India manufacture precise machinery parts based on customer preferences. Precise machinery parts are so named because they can be customized per specifications. For customized fasteners, Bhansali Techno Components, a leading high-tensile fasteners manufacturer, can be a very good option.

But, the first thing to know when ordering fasteners is the types of fasteners and their utility in various industries.

Types Of High-Tension Fasteners

There are several types of high-tension fasteners, and some of the most commonly used ones are discussed below:

- Eye Bolt

- Flanges

- J-shaped

- Bolts Plow-like Fasteners

Strength Of A High Tensile Fasteners

Several factors contribute to great tensile strength or high tensile strength. Some of those factors have been discussed here.

Diameter of The Body

Usually, the distance between two consecutive threads is referred to as diameter. Also, the larger the number of threads, the better the gripping power of the fastener. There are different ways in which this diameter is measured as ¼ -10 or ¼ -20 inch. This means that ¼ of an inch has 10 or 20 turns.

The Total Length of The Fastener

The measurement for the total length is pretty simple; it starts with the head of the fastener, which may be in the shape of a plow or eye. The other end of the is the terminal end which is where the screw or threads end.

Handedness Of Threads

If a fastener has threads, then the handedness of the thread is also important. A left-handed thread is one where the threading goes anti-clockwise, and a right-handed thread is one where the threads move clockwise.

The handedness may not directly play a role in improving the grip of the fastener. Also, the handedness of the threads used depends on the type of machine parts or fitments that are being connected.

Role Of High-Tensile Fasteners In Various Industries

Automobile Industry

Automobiles, be it modern-day cars or simple carriages all require fasteners to hold the components together. A simple carriage, for instance, needs carriage bolts, also known as cup square bolds. These have a rounded top and a square beneath. In the automobile industry, it places an overall safety of vehicles.

Clothing Industry

The textile industry makes use of the most basic type of fasteners, known as snap fasteners. Most clothes require fastening and snap buttons where two metallic parts, one with a protrusion and another with a correspondingly fitted depression, are the most primitive fasteners used in the clothing industry.

Construction Sector

This sector makes use of U-bolts, which are used in the construction sector. In situations where a pipe is to be fitted to a wall, it requires a U-shaped setup to go all the way around the pipe.

Petroleum, Oil And Gas Industry

Eye bolts are used in the petroleum, oil and gas industry. These are ring-shaped knobs or the head of the fastener that helps in attaching two or more parts. Most of these fasteners have a shoulder below the ring-shaped knob that contributes to the tensile strength of the fastener.

There are several types of eye bolts, namely Pigtail eye bolts, Screw eye bolts, and Roller eye bolts depending on the position/attachment of the know and the screw of the bolt. These are useful in attaching a chain or a rope to any surface.

Machining Industry

Machine screws are used in machine parts. These screws are used with a nut which helps join two parts of a machine together. Apart from machine screws, plow-like fasteners are used in heavy machinery as they can form tight connections with different heavy equipment components as they can form tight connections with different heavy equipment components.

Some Other Fasteners That Have Industrial Applications

Flanges

These fasteners have a circular flange at the terminal end. This flange resembles a washer and contributes largely to the tensile strength. The flange provides a large surface area and helps in distributing the clamping force over a greater area.

There are several variations of flange type of fasteners as well. There are serrated flanges where the serrations provide extra grip. Flanges are frequently used in the oil and gas industry. The role of high-tensile fasteners like flanges is often seen in high-pressure applications.

Wood Screws

As is evident from the name, these screws are used to attach different machine parts to wooden surfaces. However, there is no uniformity when it comes to wood screws; there are different types named slotted wood screws.

J-Shaped Bolts

As the name suggests, this type of tensile fastener is shaped like the English alphabet J or an anchor. These are most commonly used in gardens and amusement parks to secure different parts of playground equipment. They are also used in structural applications like securing the walls to concrete.

Summing Up

To sum it all up, it can be said that the role of high-tensile fasteners in industrial applications cannot be undermined. They are of various types like bolts, screws, washers, etc. There are grades for fasteners like grade one, grade two, grade eight etc., and the higher the grade, the better the ability to withstand stress and not fall apart under high tension.

The threading on the axis of the screw, the surface area of a bold, and the handedness of the threads of a screw all help the faster perform their job.

High-tensile fasteners play a crucial role in various industries, including automotive, construction, aerospace, and manufacturing. Bhansali Techno Components, as a manufacturer or distributor of high-tensile fasteners, likely serves these industries by providing products that offer specific advantages and functions