The Importance Of Ensuring Quality In The Automotive Sector

Quality cannot be compromised in any industry. Whether in manufacturing, automotive, or any other sector, quality plays a vital role. Maintaining quality control ensures that every product coming out of the production line meets the quality standards. One field where maintaining quality standards is essential is the automotive sector.

Why does quality assurance play a crucial role in producing components for automobiles? Every vehicle must adhere to regulations and safety protocols during the manufacturing process. They undergo safety evaluations and examinations before reaching consumers. Therefore, prioritising quality management is imperative for every manufacturer.

Below is a complete guide to the importance of quality control in the automotive industry. This article delves deeper into the realm of quality management.

Understanding Quality Control In The Automotive Industry

The primary objective of quality control is to ensure that the vehicles do not have any technical issues or bugs. After all, nobody wants to compromise the customer’s safety. To ensure utmost safety, the vehicle, parts, etc., undergo rigorous testing. The automotive industry must focus on quality, as this will help avoid high-profile recalls. Recalls are common, and the top reason is safety concerns.

The quality control process begins before the first production model is rolled off at the shop. The first step is to build a prototype. This prototype undergoes testing to find any problems. After the prototypes are evaluated and rectified, the design is transferred to the assembly line, quality control is assessed, and progress is documented. Again, after manufacturing, the product is re-examined to solve issues such as leaks, fluid, air leaks, product assembly, etc.

Why Does Ensuring Product Quality Hold Significance In The Automotive Industry?

Quality control can benefit almost every industry, including the construction and automobile industries. Superior quality must be ensured to produce high-quality materials.

However, have you ever wondered about the advantages of auto components? And why is it essential to maintain quality standards during the production of vehicle parts? If not, then let’s delve into why quality control holds importance in the automotive sector:

Cost Reduction

Quality control helps reduce costs, thus saving you money. While investing in premium-quality auto products may appear costly, it proves to be a cost-effective decision in the long term. Neglecting quality control can lead to expensive ventures, such as the customer returning the product.

Substandard products also pose risks of car accidents and jeopardise driver safety. This is why you must always opt for reliable auto component manufacturers in India and be assured of the quality.

Identify the issues

Furthermore, quality control aids in identifying problems before products hit the market. It ensures that these items meet industry standards. Through examination of quality metrics, feedback mechanisms, and root cause analysis, manufacturers can pinpoint areas for enhancement and innovation.

This emphasis on quality control nurtures a culture of learning and adjustment. It empowers employees to tackle quality issues proactively.

Maintaining The Supply Chain

In addition to quality control practices, the automotive industry relies on a network of suppliers and partners to maintain high standards throughout the supply chain. Quality control goes beyond organisations and involves efforts with suppliers, subcontractors, and distributors. By implementing quality assurance, you can ensure your suppliers that you have followed the quality benchmark. Moreover, fostering transparency is critical to maintaining relationships with suppliers.

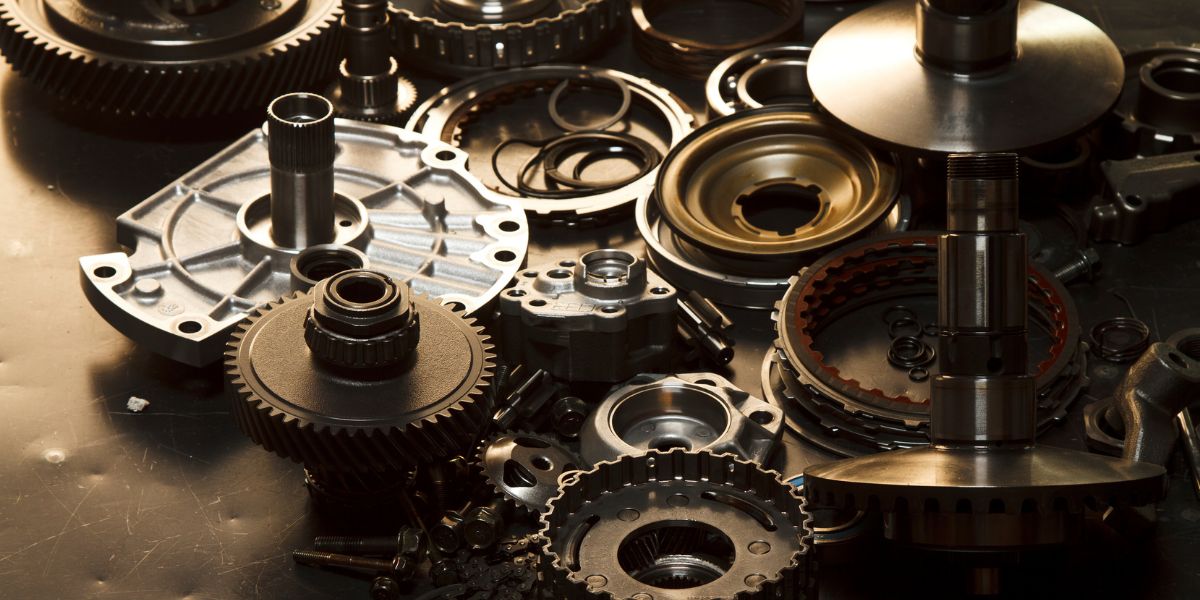

Importance Of Precision Components In the Automotive Industry

Precision auto components are the foundational base of automotive innovation. They ensure that your vehicle functions smoothly and are designed to meet modern quality standards of reliability, efficiency, and safety. The benefits of precision machining include:

Improved Product Quality

Reliable manufacturers in India use high-quality and innovative Computer Numerical Control machines. These machines help them produce top-notch quality parts. Reliable and experienced precision components manufacturers, such as Bhansali Techno Components, ensure that all the components are of good quality and do not compromise the safety of their customers. If you want to provide your customers with safety assurance, always go for professionals and experienced manufacturers.

Enhanced Component Performance

One of the often overlooked advantages of precision-turned components is that they can reduce maintenance requirements. Machined parts crafted with precise tolerances and smooth finishes fit together seamlessly, reducing friction, vibration, and wear. This improved performance directly contributes to vehicle efficiency, reliability, and durability. So, it automatically lowers maintenance costs and increases uptime. Thus, it saves money and also provides customers with the best experience.

Customer Satisfaction

The primary objective for businesses across all sectors is customer satisfaction. Using high-quality precision components helps you gain the trust of your customers since it improves the vehicle’s performance, comfort, and efficiency. Whether it is the functioning of a transmission system or the accuracy of a fuel injection mechanism, these components enhance the driving experience and leave a lasting impression on customers.

Enhance Sustainability

Society’s growing focus on awareness is pushing businesses to explore sustainable solutions. Precision components play a role in promoting sustainability due to their efficiency and durability. They contribute to energy conservation, waste reduction, prolonged lifespan, and more—ultimately promoting eco practices. Because, at the end of the day, protecting the environment is a noble cause, right?

Personalisation

Through innovative machines, manufacturers can create designs, optimise component structures, and explore new avenues in automotive engineering. This leads to the development of performance automotive parts tailored to specific vehicle models. Reliable manufacturers will provide you with the option of customisation. You can ask them to design parts of different shapes and sizes according to your requirements. It enhances customer satisfaction and sets brands apart.

Conclusion

In summary, quality control plays a crucial role in the automotive industry. It not only ensures quality but also enhances safety and efficiency. Quality control ensures that products meet international standards, satisfying customers’ needs. Quality control also cuts costs, enhances safety measures, boosts performance levels, and drives innovation. Remember that it is vital to adopt quality control procedures throughout production universally. So, to ensure you get the best components, always opt for professional and reliable manufacturers in India.