An Evaluation of Different Types of CNC Machines

A CNC(Computer Numerical Control) machine is a robotized equipment that adheres to specific instructions for precise operations like cutting, penetrating, processing, and turning on a variety of materials, including metals, plastics, wood, and composites. There are many types of CNC machines, each developed for a specific purpose in various industries.

In this article, you will learn about all types of CNC machines and their applications in various industries.

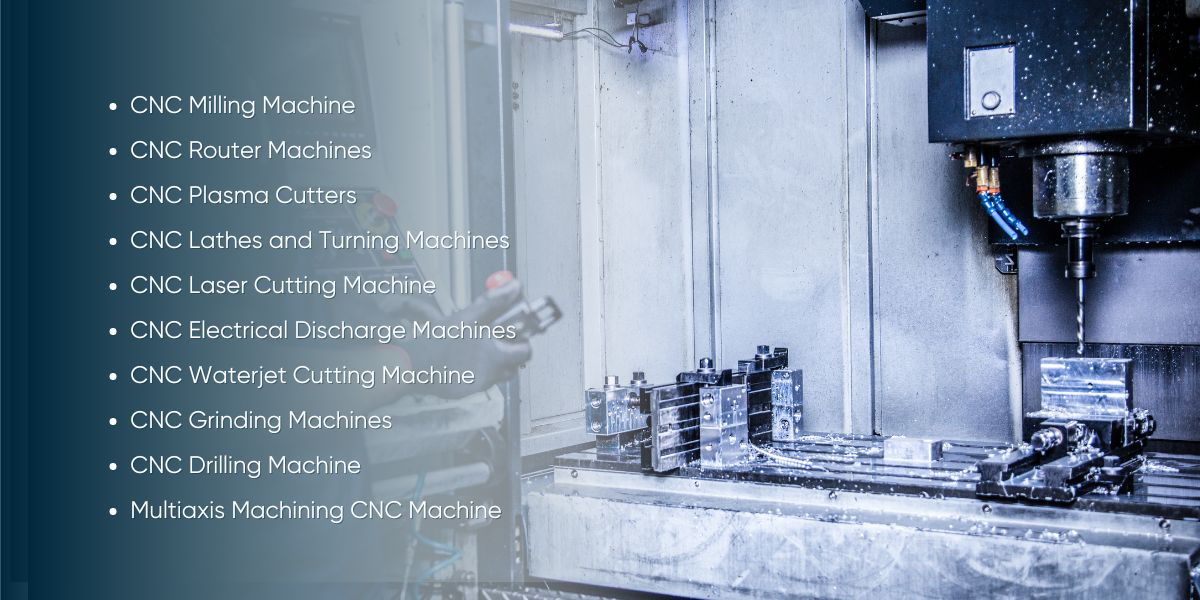

Different Types of CNC Machines and Their Application

Here is a glance at the various sorts of CNC machines and their applications across different industries:

CNC Milling Machine

CNC milling devices are accurate cutting equipment. It uses rotary cutters to take away material from a workpiece. This machine is adaptable and can execute a range of tasks. These machines produce complex parts with great accuracy.

Industries of CNC Milling Machines

- Automotive Industry

- Aerospace industry

- Metal fabrication

- Medical Industry

Importance of CNC Milling Machines

- This machine provides constant quality and accurate dimensions.

- It is capable of constructing complex shapes and patterns.

- It reduces labor expenses and increases manufacturing efficiency.

CNC Router Machines

CNC Router machines cut, etch, and shape wood, plastic, and metal materials. They utilize a pivoting cutting device (switch) with exact directions from computer-aided design (PC Helped Plan) or CAM (PC Supported Assembling) programming.

Industries of CNC Router Machine

- Woodworking

- Signage

- Prototyping

- Construction

- Art and Craft

Importance of CNC Router Machine

- It offers high exactness and repeatability in cuts and etchings.

- This machine can work with a great many materials and thicknesses.

- It reduces material waste and increases production speed.

CNC Plasma Cutters

The specialty, which is used for electrically conductive materials such as steel, stainless steel, and aluminum) of robotized machines are CNC plasma cutters. It delivers a highly accurate cut over the steel and materials.

Industries of CNC Plasma Cutters

- Metal Fabrication

- Automotive Industry

- Construction

- Shipbuilding

- Industrial Manufacturing

Importance of CNC Plasma Cutter Machine

- Plasma cutters can cut thick metals quickly, reducing production time.

- It provides high accuracy in cutting complex shapes and designs.

CNC Lathes and Turning Machines

CNC Lathes and turning machines are PC-controlled devices that turn a workpiece while a slicing instrument kills material to make barrel-shaped leaves with high precision. These machines are fundamental in assembling for their capacity to create complex shapes and accomplish tight resistances.

Industries of CNC Lathes and Turning Machines

- Automotive Industry

- Aerospace Industry

- Medical Industry

- Industrial Manufacturing

- Electronics Industry

Importance of CNC Lathes and Turning Machines:

- This machine gives top-calibre, reliable outcomes.

- It can create many parts, from easy to complex calculations.

- Lathes and turning machines reduce cycle times and increase production throughput.

- Minimizes material waste and reduces labor costs.

CNC Laser Cutting Machine

CNC laser cutting machines are PC-controlled machines. These machines are used in various endeavours for their ability to cut through different materials quickly and highly focused laser beams to cut sheets of any material.

Industries of Laser Cutting Machine

- Metal Fabrication

- Automotive Industry

- Aerospace Industry

- Electronics Industry

- Medical Industry

Importance of Laser Cutting Machine

- It provides clean and precise cuts with minimal material waste.

- This machine increases production throughput and reduces lead times.

- It considers the production of unpredictable and point-by-point plans.

- It upgrades efficiency and consistency in cutting activities.

CNC Electrical Discharge Machines (EDM)

CNC EDM are exact machine instruments that use electrical deliveries (streaks) to shape and approach workpieces. These machines are utilized to make complex shapes and examples in hard metals that are challenging to machine with customary cutting apparatuses.

Industry Application Uses CNC EDM Machines

- Tool and Die Making

- Aerospace Industry

- Medical Industry

- Automotive Industry

- Electronics Industry

Importance of CNC EDM Machines

- It provides high accuracy and intricate detailing.

- This machine can work with hardened steel and exotic alloys.

- It enables the production of complex geometries and fine details.

- It reduces material waste compared to traditional machining.

CNC Waterjet Cutting Machine

CNC waterjet cutting machines utilize a high-pressure fly of water, frequently blended in with grating particles, to slice through different materials. These machines offer flexibility and exactness in cutting many materials without creating heat-impacted zones or mechanical burdens.

Industries of CNC Waterjet Cutting Machines

- Metal Fabrication

- Stone and Tile Cutting

- Aerospace Industry

- Automotive Industry

- Glass Cutting

Importance of CNC Waterjet Cutting Machines

- This machine furnishes perfect and exact cuts with tight resistance.

- It can cut many materials, including metals, stones, glass, and composites.

- Waterjet cutting machines minimize thermal distortion and material warping.

- They reduce material waste as compared to traditional cutting methods.

CNC Grinding Machines

CNC grinding machines are PC-controlled instruments that utilize a pivoting grating wheel to eliminate material from a workpiece, accomplishing high-accuracy surface completions. These machines are fundamental in assembling for their capacity to deliver exact and smooth surfaces on parts.

Industries of CNC Grinding Machine

- Precision Bearings

- Aerospace Components

- Medical Devices

- Automotive Industry

- Tool and Die Making

Importance of CNC Grinding Machine

- This machine provides precise and consistent surface finishes with tight tolerances.

- It produces smooth and uniform surfaces, reducing friction and wear.

- Grinding machines ensure components meet exact specifications for proper fit and function.

- Able to crush many materials, this machine can work on metals, pottery, and composites.

CNC Drilling Machine

These machines are used to make with exact situating and precision. These machines are critical in assembling for their capacity to computerize penetrating tasks and accomplish predictable outcomes.

Industries of CNC Drilling Machines

- Aerospace Industry

- Automotive Industry

- Construction

- Electronics Industry

- Medical Devices

Importance of CNC Drilling Machine

- It provides precise hole positioning and depth control.

- CNC drilling machines reduce material waste and improve workflow efficiency.

- Ensuring consistent quality in drilled holes, this machine guarantees reliable component assembly.

Multiaxis Machining CNC Machine

Multiaxis machining CNC machines are advanced gadgets for moving cutting devices along various hatchets. These machines offer redesigned versatility and exactness, making them crucial in present-day creation.

Industries of Multiaxis Machining CNC Machines

- Aerospace Industry

- Automotive Industry

- Medical Industry

- Tool and Die Making

- Prototyping

Importance of Multiaxis Machining CNC Machine

- It gives high exactness and repeatability in machining tasks.

- Multiaxis machining CNC machines can deal with many materials and part calculations.

- This approach guarantees predictable quality and dependability in machined parts.

Types of Multiaxis Machining CNC Machines

When it comes to multiaxis CNC machining there are different variants all are known for their different unique purposes.

- 2-Axis CNC Machine: Used for simple straight-line cuts or drill holes on a single surface.

- 3-Axis CNC Machine: It has 3 axes of movement work on all six surfaces typically cut square or rectangular blocks of material.

- 4-Axis CNC Machine: Rotating cutting tool ideal for making cutouts and cutting along an arc.

- 5-Axis CNC Machine: High accuracy in making machines, very useful for medical and aerospace equipment.

- 6-Axis CNC Machine: Create shapes of any surface finish by involving all possible directions.

- 7-Axis CNC Machine: Useful for creating complexity of parts in aerospace, medical, and military equipment.

- 9-Axis CNC Machine: Ability to manufacture both internal and external parts for dental implants, surgical tools, and complex aerospace equipment.

- 12-Axis CNC Machine: Contains two cutting heads to increase accuracy and can double production speed or even more.

Summary

CNC machines reform the present day producing with their accuracy, productivity, and flexibility, taking care of different businesses from aviation to clinical gadgets. As the market keeps on expanding, accuracy parts makers in India, such as Bhansali Techno Components, influence these cutting-edge innovations to satisfy rigid needs and remain cutthroat. Explore cutting-edge CNC machining solutions and elevate your production capabilities!