Detailed Guide: Types Of Fasteners And Their Application

Different types of fasteners play a vital role in maintaining equipment’s functioning by holding machine parts in place against excess force, vibration, and pressure. Created by precision components manufacturers, these are used to join two or more objects mechanically in a permanent or non-permanent fashion.

While permanent fasteners, like nails and rivets, are used for a permanent joint and can be only used once, non-permanent fasteners are designed for easy removal and re-use and consist of bolts, pins, and screws.

Both fasteners are widely used in various industries and for assembly of products. There are different types of fasteners, each with their purpose. Read on to learn more about different fastener types and the role of high-tensile fasteners.

Different Types Of Fasteners

Various high-tensile fastener manufacturers in India produce a variety of permanent and nonpermanent fasteners. The most commonly used fasteners can be broadly categorised into:

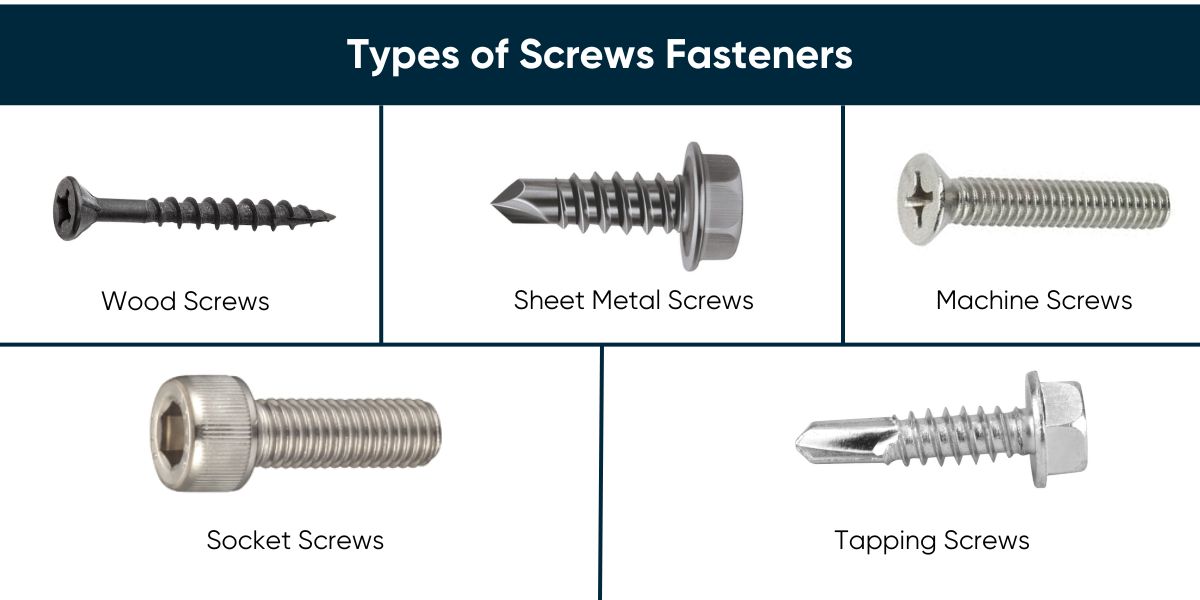

1. Screws Fasteners

One of the most common types of fasteners, screws, are used for residential as well as industrial purposes. These fasteners have an external self-threading, enabling them to fit into components without tapping.

A screw is used to hold two objects together and can be of the following types:

Wood Screws

These types of fasteners have a tapered head, enabling them to sink into the material. Therefore, they are used to join wood.

Sheet Metal Screws

Having a structure similar to that of wood screws, sheet metal screws are made for attaching metal to materials like plastic and wood.

Machine Screws

These screws are thicker in size and have a high tensile strength, enabling their use in machinery and appliances. In addition to external threading, they also contain internal threads and have a cylindrical head.

Moreover, machine screws can easily be inserted into pre-drilled holes. These fasteners are available in different lengths, sizes, and diameters, making them one of the most widely used and versatile types of fasteners.

Socket Screws

Used as permanent fasteners for sheet, wood, metal, and other materials, socket screws require an Allen key. These screws can be further divided into different types based on their head shapes, such as socket, flat, and button heads.

These generally offer high-quality results and superior robustness compared to other mechanical fasteners.

Tapping Screws

Designed to be tapped directly into pre-drilled holes, tapping screws are designed with a pointed tip and threaded shank. These are, therefore, ideally used in metal sheets.

Tapping screws provide high strength and resistance to shock and vibration, making them useful for automobile and construction projects.

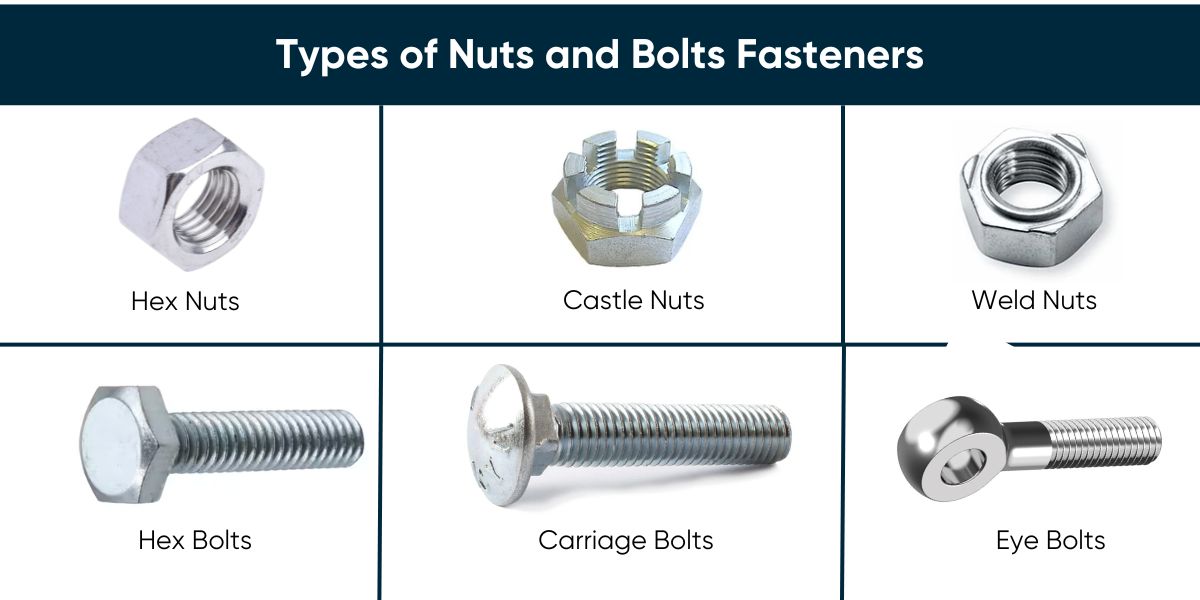

2. Nuts And Bolts

Nuts and bolts are commonly used to connect separate pieces. While the bolt is inserted to join the parts, nuts secure the bolt on one end. In general, these are used to join metal to wood.

Following are a few common types of nuts and bolts:

Hex Nuts

Hex nuts, made from high-quality steel and available in different sizes, are commonly used in wood and metal projects. They have a six-sided head and can be easily tightened with a wrench.

Castle Nuts

Used for mechanical fastening, castle nuts have slots or notches on one end to enable the placing of pins, helping secure them in place. This makes it ideal for projects requiring low torque levels and a tight connection, as their removal requires removing the pins first.

Weld Nuts

Weld nuts, which have an internal thread with a slap or rounded head, are commonly used in industrial applications to secure components to difficult-to-reach surfaces.

These nuts are welded into place, ensuring a permanent connection between wood and metal sheets.

Hex Bolts

Commonly used in machining and hardware industries, hex bolts have a hexagonal shape with internal threads, allowing them to be screwed into threaded holes. These are generally used for securing metal and wood connections.

Carriage Bolts

These bolts, used for wood joining, have square necks and convex metal heads. They also have internal threads, creating a self-locking and secure connection. These types of bolts don’t require pre-drilled holes.

Their flat head also makes them ideal for furniture construction and outdoor projects, providing high-quality results.

Eye Bolts

Eye bolts, which are used to attach a chain to any surface, have a circular ring and internal threads. Moreover, these high-tensile bolt grades have a smooth shank, enabling extra strength for joining metal to other materials.

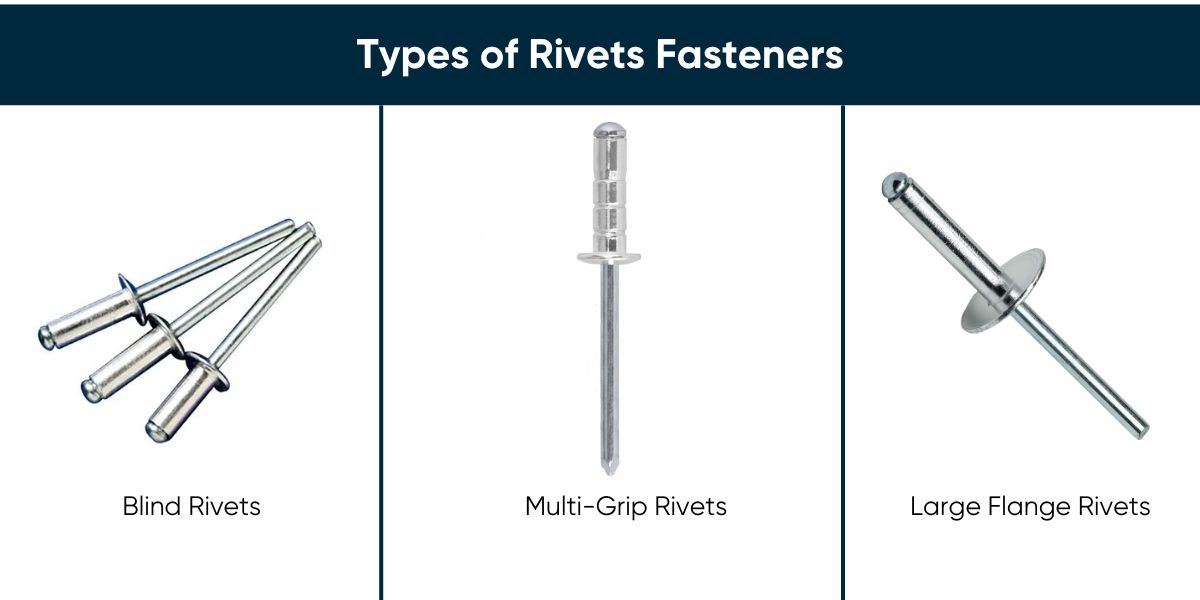

3. Rivets

Rivets are permanent fasteners used in industries to fasten metal sheets and plates together. They are ideal for high-strength applications and provide a single-use, unremovable solution.

Rivets generally have a cylindrical shape with a long shank. The head can be hexagonal or rounded.

Blind Rivets

These rivets have a tubular design and may be open-end, with an oval-shaped head and internal threads, or closed-end, with a rounded head and smooth shank, enabling their use where one side of the assembly is inaccessible.

Multi-Grip Rivets

These are used in case the installed materials have differing thicknesses, as they can expand to the required size.

Large Flange Rivets

These types of rivets have larger washers on their hats, enabling quick and efficient joining of materials.

4. Washers

Washers also find applications in multiple industries. However, they are generally used with joints and nuts, helping prevent the loosening of components due to vibration and reducing friction.

In addition, washers can help prevent leakage by isolating different components. Depending on their application, these can be made of plastic, metal, or rubber. Different types of washers include:

Flat Washers

These help distribute the load of a screw, bolt, or nut in an even manner and secure the attachment.

Spring Washers

Also known as split washers, spring washers can increase tension in bolted joints and help prevent the loosening of nuts and bolts. They can be made of plastic or metal and have a split down one side.

This split enables them to act as springs between two surfaces, adding flexibility and reducing vibration.

Ribbed Washers

With their raised edges or teeth, these washers help provide extra strength and grip to a joint. They are commonly used with bolts or threaded rods.

5. Nails

One of the most common types of fasteners found in every household and construction project, nails are available in multiple shapes and sizes. While the general nail is characterised by a large and flat head and a thick shank, other types of nails include:

Finishing Nails

These are smaller, and their flat heads allow them to blend in with the surface. They are commonly used for crown molding.

Box Nails

They have a steep shaft and diamond-pointed tips, enabling their use in framing and construction.

Choosing The Right Fastener For Your Industry Application

Selecting the right type and size of fastener according to your requirements is essential for a long-standing and secure joining. Therefore, when selecting a fastener, you must consider its application and the properties you require with the best high-tensile fastener manufacturers in India.

Once you have decided on the type of fastener you need, you can source them from top manufacturers, such as Bhansali Techno Components, who can provide you with high-quality products.