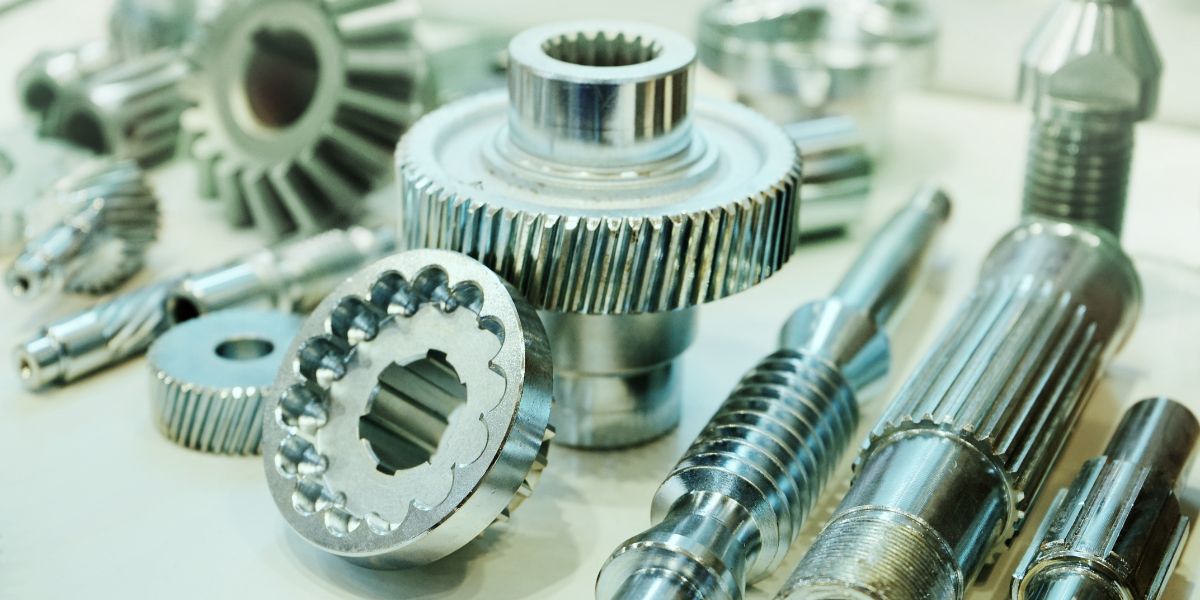

Detailed Guide To Know About Types Of Pins In Industry Application

Pins are handy and are used in several industries, where they act as imperative mechanical fasteners to hold or join together two or more objects. These range from simple straight pins to spring-loaded types of industrial pins that are unique when used in manufacturing, construction, and engineering.

The World industrial fasteners market, including pins, has been estimated to be $108.47 billion by 2029. It is forecasted to grow at a rate of 4.26% between 2024 and 2029. This growth proves the necessity for the products in specialized pins in various industries across the global markets.

Various Types Of Pins

The knowledge of these different forms of pins and their uses is essential for proper choice and employment in so many industrial operations. Following are the various types of pins:

Cotter Pins

Cotter pins are relatively plain, semicircular metal clamps intended to be passed through a hole in a shaft, an axle, or a bolt to eliminate relative movement between such elements. These basic gadgets, especially those manufactured by precision components manufacturers, are of immense use in the automotive and aviation industries and construction. Cotter pins operate under high vibrations in a way that locking screws would come off.

Pros:

- Simple and cost-effective.

- Reliable in high-vibration settings.

Cons:

- Limited load-bearing capacity.

- Require periodic inspection and replacement.

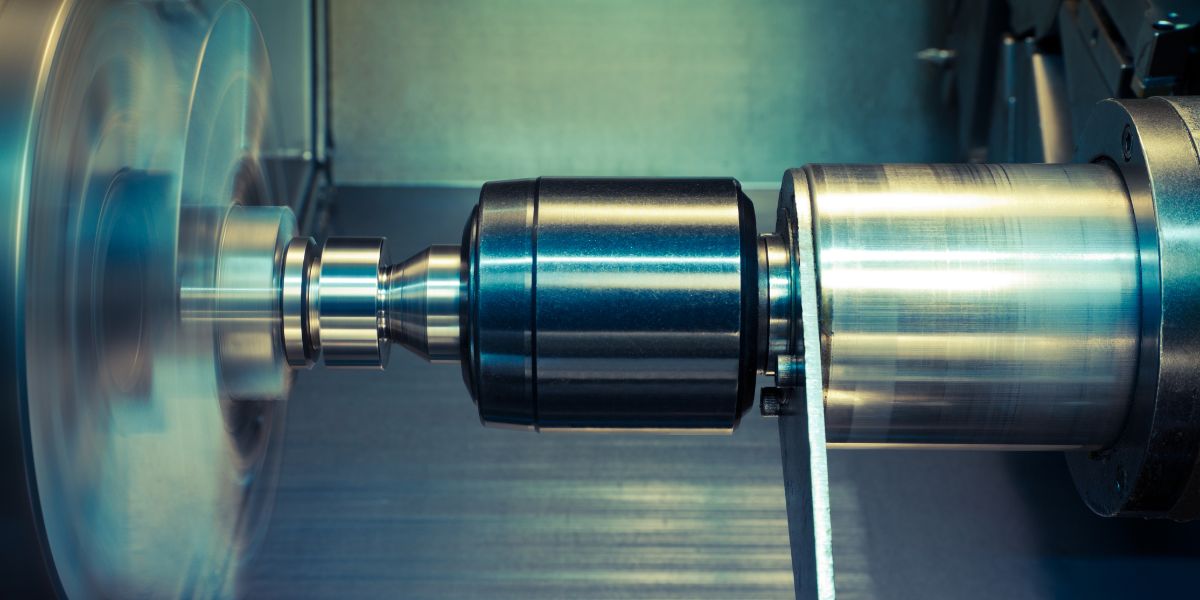

Dowel Pins

Dowel pins are stiff bar-shaped elements used to locate, fasten, or enhance the load-bearing joints of different assemblies. Because of their precision alignment and load-bearing capabilities, they are useful to various industries. Dowel pins are crucial, but spindle manufacturers ensure accurate positioning in machinery. They help maintain proper alignment in high-speed rotating parts.

Pros:

- Self-centring capability in slightly misaligned holes.

- Allow for thermal expansion without losing alignment.

Cons:

- Create stress concentration points in certain materials.

- Potential for loosening in applications with high vibration.

Lynch Pins

Lynch pins are fasteners fitted on items or assemblies that may be often disconnected later on. It is in this group of industrial pins and is relevant in the frequent interchanging of components industries. In agriculture, they join implements to tractors, construction, and automotive parts. They’re crucial for safety and efficiency in these applications.

Pros:

- No tools are required for use.

- Secure fastening under load.

Cons:

- Not suitable for high-precision alignments.

- Potential for accidental release if not properly secured.

Spring Pins

Coiled pins, roll pins as well as spring pins are cylindrical fasteners with a slit along their length to enable them to reduce in diameter when engaged in a hole. The more popular types of thermoplastic are used in several industries because of their uniqueness in certain properties. In the transportation industries such as automotive, aerospace, and manufacturing industries, we find the spring pins in alignment, pivoting joints, and holding of components.

Pros:

- Self-retaining design.

- Absorb shock and vibration.

Cons:

- Not suitable for all materials.

- Limited reusability after removal.

Wire Lock Pins

Wire lock pins also called quick-release pins or detent pins are fasteners or pins that can be inserted and removed easily, with a great level of locking performed on them. They include the pin body with a spring facility that holds a ball and a wire ring for enhanced control. These pins are essential in aircraft manufacturing, military hardware, and other manufacturing industries where frequent connection and disconnection are necessary.

Pros:

- Resistant to vibration loosening.

- Versatile for various hole sizes.

Cons:

- Potential for spring mechanism failure over time.

- Not suitable for applications requiring permanent fastening.

Taper Pins

Taper pins are unique among industrial fasteners that create a tight, precise fit through a wedging action. This characteristic makes them invaluable in the machine tool industry, where they’re often used to locate cutting tools accurately. In the automotive industry, taper pins are crucial for assembling transmission components and engine parts where alignment is critical.

Pros:

- Excellent for transmitting torque in small spaces.

- Provide a means of fine adjustment in precision assemblies.

Cons:

- This may cause stress concentration in the surrounding material.

- Difficult to automate installation in high-volume production.

L-Handle Pin

L-handle pins are known as T-handle pins or pull pins. These are quick-release fasteners. It has an L-shaped handle. They are useful in cases where constant and easy adjustments without tools, or constructions that need fast assembly and disassembly. These pins are widely used in fitness equipment, industrial machinery, and agricultural implements.

Pros:

- Provide leverage for insertion and removal in tight spaces.

- Often incorporate locking mechanisms for added security.

Cons:

- Generally more expensive than simpler pin designs.

- Limited load-bearing capacity compared to fixed pins.

Clevis Pins

Clevis pins are cylindrical fasteners. It is turned through an angle with at least one member connected to another. Generally, they will include a head on one end and a hole for a cotter pin or ring on the other. Clevis pins are essential in industries where there is a need to have a locking pivot. These pins are utilized in automobiles, aerospace, naval, and construction fields. They are used in operations such as auto suspensions, aircraft, operations, and piece of machinery connection.

Pros:

- Easy to install and remove for maintenance.

- Can handle high loads in shear.

Cons:

- Can experience wear over time, especially in high-cycle applications.

- Potential for galvanic corrosion if materials are not properly matched.

Detent Pins

Detent pins are spring-loaded fasteners with retractable balls that lock into position when inserted. They are essential within sectors that demand rapid, safe, and standard coupling. It is known as a detent or key-stop pins. It is utilized for tool changers, jigs, and equipment with four or more interchanging parts commonly applied in aerospace, automotive, and manufacturing industries.

Pros:

- Quick insertion and removal.

- Ability to withstand vibration.

Cons:

- Complex and more expensive than simple pins.

- Potential for jamming in dirty environments.

Retractable Spring Latch Pins

Retractable spring latch pins can be described as fasteners with a spring that closes an element of the fastening. They are useful in operations in industries where it is necessary to have a fast and easy-to-release connection that can be done with a single hand. These pins are significant to aerospace, automotive, and material handling applications where removable components, barriers, and equipment that need adjustment are necessary.

Pros:

- Self-locking mechanism for added security.

- One-handed operation.

Cons:

- The spring mechanism can weaken over time.

- It is not suitable for applications with extreme temperature variations.

Get In Touch With Us For Custom-machined Pins For Your Application

The diverse range of industrial pins across various sectors offers unique advantages. These fasteners are useful in solving alignment, locking, and simple release problems from the simplest cotter pins to the most sophisticated detent pins. Today, the market for industrial fasteners is rising globally and fluently, and businesses like Bhansali Techno Components are ready to produce precision components to fulfil their demands. Ready to pin down your success? Connect with us now!