What Is Vmc Machine: Learn About Its Unique Advantages And Applications

If you belong to the modern manufacturing industry, you must have an idea about What is VMC machine. This multi-functional machine has been used in manufacturing processes for the past 150 years or more. It ensures high precision and efficiency, resulting in increased manufacturing productivity. This advanced machining tool can quickly and efficiently handle complicated metal processing.

The article below explains the essence of this high-end machining tool and its unbelievable applications. It also explains its predominant uses in modern-day industries.

What Is Vmc Machine?

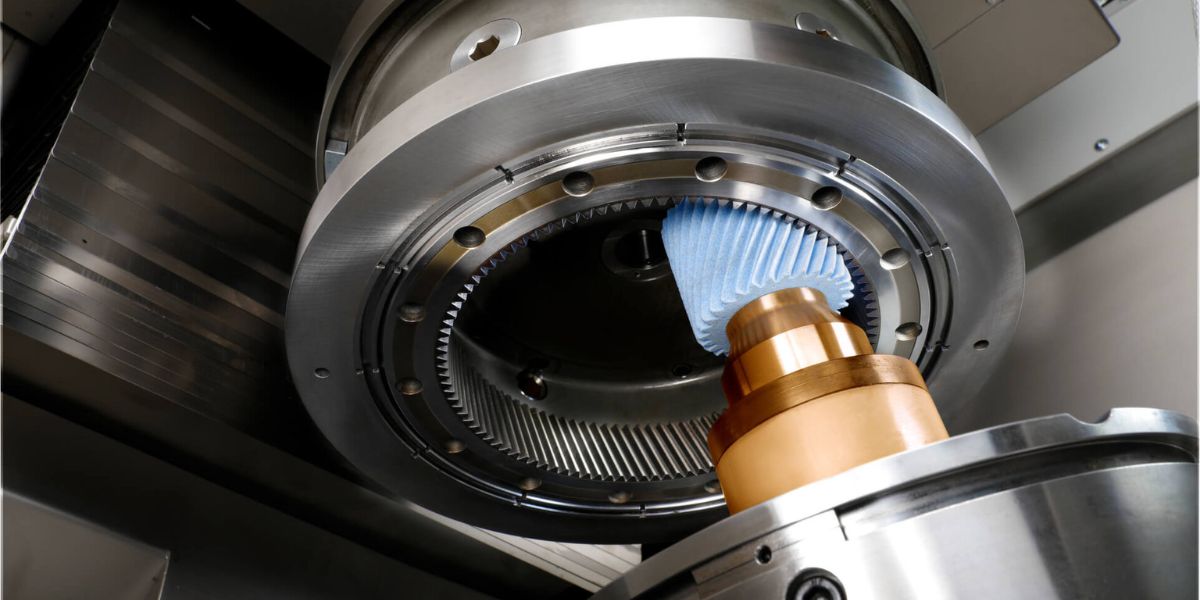

Some people know a VMC machine as a milling machine because its sharp rotary cutters detach or pull metal from workpieces. In machinery manufacturing units, these tools deal with mass production and high-precision needs in textile and light, instrumentation, automobile, aerospace, mold making, electrical and electronic, handicrafts, military products, etc.

What Are The Major Applications Of A Vmc Machine?

Complex-shaped workpieces are processed with precision and high accuracy using these tools. Hopefully, you have gained a basic idea of what is VMC machine. Now, let’s concentrate on its prime applications.

Precision Machining

Precision machining activities are primarily found in the defence, energy, and electronics sectors. In this respect, VMCs perform a wide array of challenging tasks involved in high-volume manufacturing, small-batch production, and prototyping. These tools dexterously deal with diversified machining challenges while maintaining high-quality performance and versatility. They can also handle complex and intricate parts with tight tolerances, which is why precision component manufacturers prefer these machining tools so much.

Fabrication Of Medical Devices

Quality and precision are the two strongest pillars of the modern-day medical device-making industry; thus, these two factors cannot be compromised. Here comes the actual role of the vertical machining centre. Complex components like prosthetic devices, surgical instruments, and orthopedic implants can be dealt with only by these advanced machining tools. Since VMCs can work with different materials, including titanium and stainless steel, they are treated as the most suitable option for fabricating medical devices.

Automotive Manufacturing

There is no automotive part manufacturing unit today that does not know what is VMC machine. The recent automotive industry has involved extensive VMCs to facilitate the manufacture of auto components like brake systems, chassis parts, transmission components, engine blocks, and others. Due to this tool’s versatility, production processes can be effectively streamlined, maintaining a perfect competitive stand.

Aerospace Industry

The significance of VMC tools in this specific industry is relatively high primarily because of their unbelievable precision, efficiency, versatility, and reliability. These tools manufacture different complex components like structural components, engine parts, and aircraft frames. They help meet the aerospace industry’s stringent rules and standards, especially while machining materials such as composites, titanium, and aluminium.

Mold Making

Mold making procedures usually involve the making of molds utilized in die casting, injection molding, plastic injection molding and other relevant manufacturing processes. Mold-making cannot be completed without milling precise contours and cavities. In this respect, VMCs play the most significant role.

Die Making

Die-making industries also extensively use VMCs to make dies, which are utilized chiefly for metal stamping. Die components, especially inserts, dies, and punches, are accurately machined, maintaining acute precision. These components are used for metal forming procedures.

Rapid Tooling And Prototyping

Rapid tooling and prototyping applications often need quick adjustments and iterations facilitated by only VMC tools. With the help of these unique machining tools, manufacturers can now enjoy the advantages of making cost-effective tooling and prototype components.

3d Manufacturing

VMCs with high-end 5-axis, 4-axis, and 3-axis proficiencies can efficiently perform complicated 3D machining applications. The tools handle engraving, sculpting, and contouring tasks needed in the jewelry and art manufacturing industries.

What Are The Unbelievable Advantages Of A Vmc Machine?

VMCs have innumerable advantages that have benefited the manufacturing industries for years. In fact, these tools are considered the lifeline of the modern manufacturing sector. Some predominant advantages of these fantastic machining tools have been discussed below.

1. Operator-Friendly

VMC has a mind-blowing structural design that can be easily used by the operators without any hassle. This is how the milling process smoothly goes on without inviting any accidents or errors. On the other hand, the automated technology of this tool also saves a lot of time. Simple programming has been used; thus, anybody can adjust the setting to suit their convenience and requirements.

2. Versatility

Currently, VMC is used in multiple industries for diversified applications, which is why it is treated as a versatile industrial tool. Some of the critical applications of this tool are contouring, tapping, drilling, milling, and other relevant tasks in the manufacturing industry.

3. Automated Integration

VMC machines have been equipped with high-end robotic systems, which allow faster task completion. Their operation is also so easy and flexible that operators with little technical knowledge can handle them. To increase uptime, automated production runs, light-out machining, and other related robotic applications are performed.

4. Industry Adaptability

With the advancement of technology, the manufacturing industry has undergone a technical transition with the 4.0 version. VMC tools are so flexible that they have adapted the recent version smoothly. They have specialized automated technology with the help of which they can adapt all the upcoming versions automatically without any manual assistance.

These tools have recently incorporated a few unique characteristics, including Predictive maintenance, data analytics, and IoT connectivity features. These elements are used to monitor real-time machine performance, optimize machining procedures, and proactively handle maintenance scheduling, ensuring greater quality and efficiency.

Summing Up

If you want your manufacturing processes to become automated and more productive, nothing can be better than introducing the VMC tool. For more details regarding its installation and availability, you can also seek assistance from Bhanshali Techno Components. We help various industries by manufacturing precision components by using VMC machines for the proper cutting of metals.