Delve Into the Details Of Manufacturing Precision Components In Aerospace

It is a fact that aerospace is indeed synonymous with cutting-edge technology. This is where the most essential and recent innovation creeps down to make it easy for the people. From propellors to aerodynamics, the precession complements produce indispensable space to make things more meticulous. Well, be that as it may, have you ever thought about the way precision components in aerospace are making their silent entry every day? Keep reading further to know more about the intricacies of aerospace.

An Idea Of Aerospace

Before delving into further details, you must have a fair idea about an aerospace precession. An aerospace precession is a high-profile engineering design that serves the aeronautical industry. When it comes to safety, fuel efficiency, and peak performance, precision components are essential. These parts are necessary for many aircraft applications, including landing gear, engines, avionics, and structural components.

Types Of Precision Components

There are various types of precision components in aerospace that you can classify. Not all serve a similar purpose. However, you will need to know a few details.

Aero Engine Components

You need to know that precision components in aerospace are made to survive harsh circumstances like high rotating speeds, pressures, and temperatures. Fuel injection systems, combustion chambers, and turbine blades are some parts that need to be manufactured precisely to guarantee dependability and efficiency.

The Avionics Components

You need to know that the avionics component contributes to the electronic systems of the aerospace and aerodynamic industry. Especially in communication in aerodynamics, the need for avionics is an essential precision component in aerospace. However, there are a few other facts that you need to know when it comes to the matter of avionics, such as flight control, accuracy, and control interfaces. All can be handled with avionics.

Landing Gear Components

Yet another aerospace precession is the gear components for landing. To enable safe landings and take-offs, landing gear components like wheels, braking systems, and shock absorbers must be produced precisely. The general safety of the aeroplane depends on the reliability of these parts. You need to know that reputed and quality high-tensile fastener manufacturers make sure to provide industry-standard devices that are designed with precision.

The Structural Components

Aerospace precession is a broad concept. Instead, it is the combination of tiny detailed processes working together. One such is the tail sections, fuselage panels, and wing assemblies. These are a few examples of precisely engineered parts essential to an aircraft’s structural integrity. A thorough quality control procedure is employed on these parts to ensure their robustness, longevity, and aerodynamic effectiveness. It is not for nothing; precision components manufacturers in India design products that deliver the utmost accuracy.

Getting An Insight Into The Details Of Precision Components Manufacturing

You must have grown an intense interest in precision components in aerospace, or you are into the aeronautic industry. The reason you have landed on this article can never be for mere reading sake. Thus, you must know about Bhansali Techno Components and how they assess precision.

Crucial components involved in the process of precision manufacturing are:

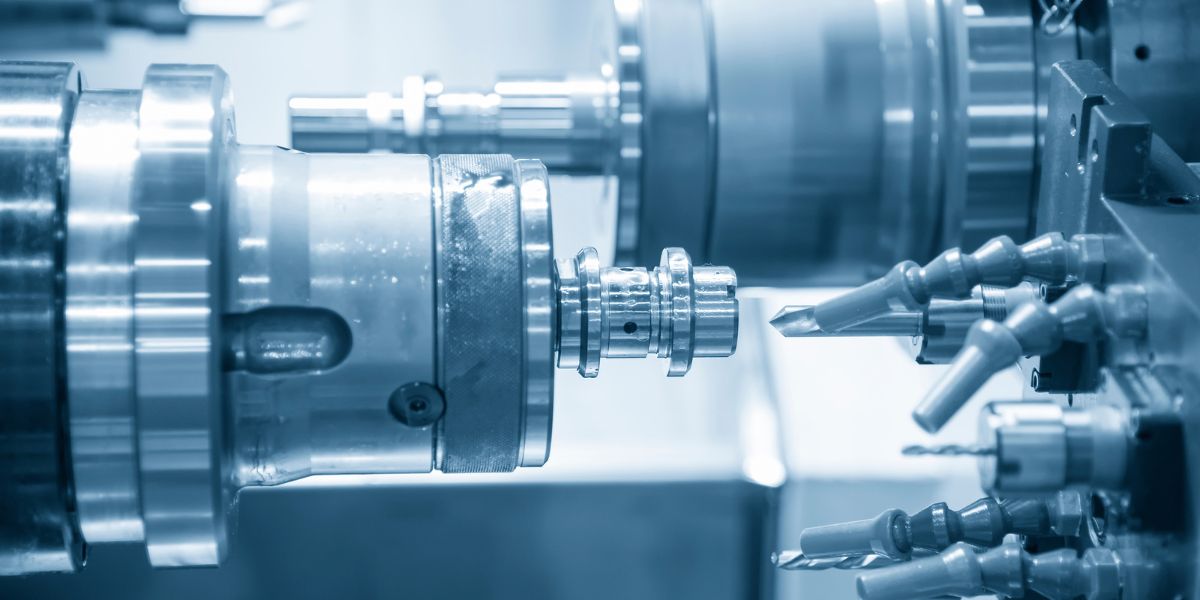

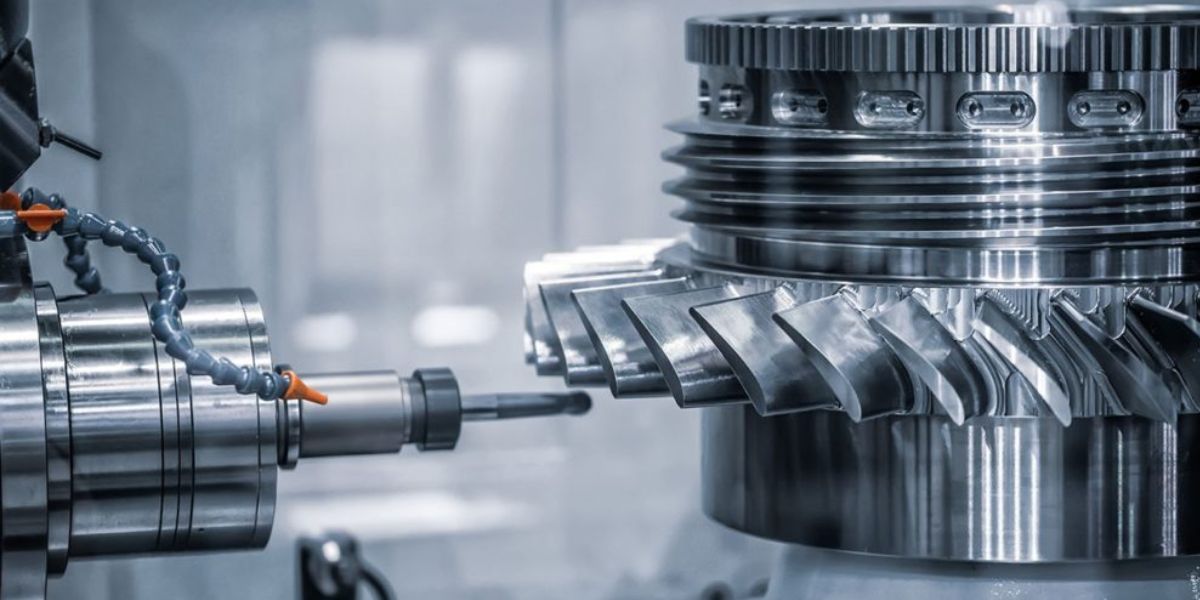

The CNC Machining

One of the key elements in precision manufacturing is CNC machining. You need to know that computer numerical control (CNC) machining is a popular manufacturing technique in the aerospace sector. It allows the industry to create complicated and complex components exactly. Structural components, avionics housings, and engine parts are all made utilizing CNC machining.

Additive Manufacturing

Additive manufacturing or 3D printing is another precision component in aerospace manufacturing processes you need to know. Aerospace can produce intricate details with less or zero waste through these manufacturing processes. You need to understand that this process is employed by creating prototypes of a lightweight structure.

The EMC (Electrochemical Machining)

There is a good reason why high-tensile fastener manufacturers produce high-quality ECM for aerospace engineering. The ECM that Electrochemical Machining is used to fabricate components that demand a high degree of precision. It happens mainly where intricate shapes play an essential role. This unconventional machining method removes material from the workpiece using electrical energy to achieve tight tolerances and smooth surface finishes.

Inject Molding

You must know that Bhansali Techno Components employs injection moulding to produce plastic and other components. This process is ideal for creating parts that weigh light. For instance, in aerospace, this procedure is used for non-structural elements.

A Few Challenges And Future

There is no doubt that innovation comes with a lot of challenges and futuristic designs. The sheer futuristic design allows the precision components in aerospace to sustain in such an ambience where, each day, innovations sweep away the old ones. So, you will need to know some future trends and challenges.

Innovation In Materials

The materials used for aerospace have advanced greatly. Advances in material science are still driving the component advancements. The advancement of materials led by precision components manufacturers in India comes with high strength and low weight and improves performance in general and fuel economy.

Smart Components

The integration of smart tech is indeed engulfing the entire world. The aeronautic industry is not an exception. The introduction of intelligent technologies allows data to be transferred much more quickly. This allows the industry to enter into the realm of real-time monitoring and performance.

Resilience In The Supply Chain

Supply chain interruptions pose a problem to the aerospace sector. The sector’s future depends on developing robust supply chains, looking into local sourcing opportunities, and implementing digital technology for enhanced supply chain management.

The Environmental Considerations

With the growing emphasis on sustainability, aerospace manufacturers are exploring ways to attain sustainability. The introduction of sustainable materials in aerospace is a hope for the future.

The Final Word

In the aerospace sector, Bhansali Techno Components are the unsung heroes that make modern aviation and space exploration possible. Their intricate designs, advanced manufacturing processes, and stringent quality control ensure aerospace systems’ reliability, safety, and efficiency. As technology continues to evolve, the aerospace industry will see further advancements in precision engineering, materials innovation, and the integration of intelligent technologies, shaping the future of aviation and space exploration.