Understand Why CNC-Turned Components Can Boost Productivity

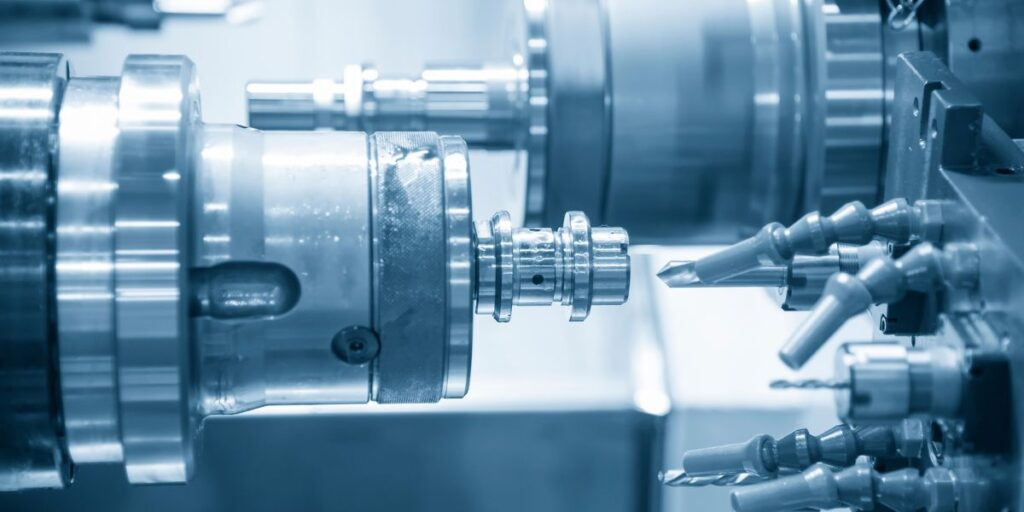

Computer Numerical Control, popularly known as CNC, turned components have been ranked as the top segment of the industrial manufacturing process. Every company using CNC to produce its components or parts has gained enormous profits and increased productivity.

These precision-engineered elements manufactured using CNC offer high accuracy, less downtime, and more speed. Here’s all you need to know about CNC-turned components:

Precision And Accuracy

The CNC-turned components boost productivity primarily because of their enhanced precision and accuracy. The precision of components is the extent to which the measurements and dimensions are exact.

The CNC broaching machine is capable of manufacturing industrial pieces that have a high tolerance and are measured through micrometres. This type of production ensures that every industrial component manufactured is according to the precise specifications of the required industrial standard.

Precision and accuracy make every component free of adjustments, reworks, or manual inspections, which are computerized now. Thus, CNC-turned components help save time and resources for the company. The accuracy and precision of CNC-turned components are necessary for industries like aerospace, automotive, and healthcare.

Reduced Setup Time

Unlike traditional machining, which requires a lot of time to set up and make adjustments for the machining process, the CNC-turned components come with the advantage of reduced setup time. Being a product of advanced technology, CNC machines are designed to provide quick and seamless setup.

Its tool changing and adjustment process is automated to save time. This automation, in turn, helps to reduce the downtime between production runs and indirectly paves the way for increased production volumes with short lead time. Here, operators have the advantage of quickly loading the CNC program and fixtures. Therefore reducing manual interventions.

Consistency And Repeatability

As an industrial components manufacturer, consistency of the product is a must. Within this industry, every component produced is part of a larger project responsible for machine functions. CNC-turned components boost productivity by maintaining consistency and repeatability.

With CNC, the operator only needs to set up the program once for specific industrial components, and the machine then produces identical parts repeatedly. It keeps up the dimensional requirements and quality of the product, which would otherwise be difficult for a manual process. The advantage of precision-turned components is reliable products are equal for all industries specifically for automotive, aerospace, and healthcare.

Complex Geometrics

Over the period, industry requirements for new and intricate designs have considerably increased. Engineers build industrial components with complex geometric dimensions to keep up the perfection of machine functions and achieve higher performances.

A traditional manual machining process will find this extensively challenging to achieve, which is now overcome by CNC machines. These machines are designed to curate new complex structures and manufacture more efficient components. Thus contributing to the idea that CNC-turned components boost productivity.

Multitasking Capabilities

Apart from precision cutting, consistency, and the ability to manufacture complex designs, the CNC machine is yet more multitasking than this. From cutting, drilling, and milling to turning, CNC machines can be all in one package for a company. Covering almost every function and responsibility of production, the multitasking feature of CNC boosts productivity to a greater extent.

With one setup, the CNC machine reduces the challenging task of transferring components to multiple devices or even minimizing setup time. This reduces downtime and increases production time, thereby increasing the amount of industrial components produced.

Improved Tool Life

One incomparable benefit of CNC machines, which boosts productivity, is their improved tool life. CNC-turned components have comparatively longer tool life, which is achieved by optimizing the cutting frameworks and constant monitoring of manufacturing of tool wear.

Automated systems in these machines enable continuous monitoring of the components produced for early detection of wear and altering for the need to replace tools. This process helps in reducing downtime associated with tool changing and replacing. It increases the productivity of components and enhances tool life.

Faster Production Speeds

Increased productivity is directly related to production speeds. CNC machines are known for their high and quick production speed that manufactures precision components. High spindle speeds with computer/automated control and toolpath programs ensure the machining process is not delayed. These machines are designed to operate quickly according to the prompts they receive and continue to do so until they achieve the target.

A faster production rate helps the manufacturers boost their sales and profits, which are otherwise not possible through manually handled machines. Enabling companies to remain consistent in their delivery deadlines and thus maintain a good relationship and brand image.

Minimal Scrap And Waste

Precision CNC turned manufacturers benefit greatly from CNC machines because it reduce the amount of scrap and waste. The programmed manufacturing process allows the machine to use what is required for precision components. This cannot be possible in the case of manually handed devices because of the amount of revision a product would undergo to achieve accuracy.

With material removal and minimized unnecessary cuts, CNC-turned components also commit to sustainability goals of the environment. Preserving raw materials also reduces the carbon footprint associated with disposing of waste materials. Thus, contributing to the fact that CNC-turned components boost productivity.

Flexibility And Customization

Manufacturers gain the advantage of flexibility and customization with CNC-turned components. It does not require an extensive process of retooling the machine, thus increasing the productivity.

The automated machine makes it possible to manufacture a wide range of industrial components that are both complex and accurate. This allows the company to offer a choice of customizing the components according to the customer’s specific needs.

Enhanced Safety

Computerized machine process reduces the involvement of operators directly with the machine. Their role primarily relates to code input and monitoring the process. This automation allows the operators to remain safe from handling heavy materials and thus minimal exposure to hazardous elements or tasks. The risk of accidents and injuries is overcome by monitoring from a safe distance.

Get CNC Turned Components From The Best Manufacturer

Bhansali Techno is a leading CNC turning components manufacturer that provides high-quality and durable customized industrial components. Made with raw materials from their plant, the company has provided some of the best and unique range of components. At Bhansali Techno Components, CNC-turned components are fabricated with minimal setup time and reduced waste materials. Thereby ensuring a long tool life and strategies to produce innovative elements.