Understanding The Cost Of Pump Shaft Price In India

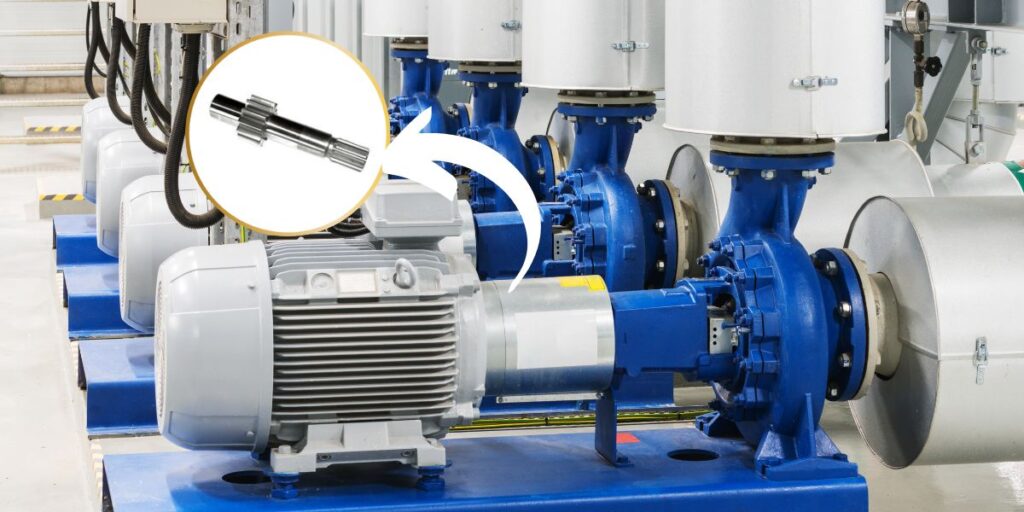

Pump shafts are really important in lots of different industries, like water treatment, chemicals, oil, and so on. They can last longer and need less maintenance compared to regular pump components. So, it is more expensive than other pump parts because of its numerous benefits and quality. Also, it is cost-efficient and lasts longer. But, what is the pump shaft price in India?

Pump shafts can cost anywhere between Rs:100 to 200,000 per piece in India. But figuring out the exact cost depends on many different things. However, determining the precise pump shaft cost necessitates considering a wide range of variables. This blog post will go into great detail about the variables that affect the typical cost as well as the average pump shaft price list in India.

Average Cost Range Of Pump Shaft

The average cost range of pump shafts can vary significantly depending on factors such as the type of pump, material, size, length, and manufacturing processes involved. The below table shows the average pump shaft price list :

| Application Type | Material | Length | Price Range(per piece) |

|---|---|---|---|

| High-Pressure Pump Shaft | SS | 7 inch | Rs: 400 |

| Stainless steel pump shaft | Steel/Stainless Steel | 300 mm | Rs: 500 |

| Automotive Use Pump Shaft | SS304 | 1 m | Rs: 2000 |

| Submersible Pump Shaft | SS420 | 2 feet | Rs: 400 |

| Chemflo Pump shaft | MS | 1.2 m | Rs: 1350 |

| StandardMud Pump Shaft | SS | 10 inch | Rs: 4500 |

| Water Pump Shaft | Cast Iron | 600-700 mm | Rs: 5000 |

For accurate pricing, it’s best to consult with pump manufacturers or suppliers who can provide quotes based on your exact specifications.

Cost Consideration Factors Of Pump Shaft

Cost considerations in pump shafts include several variables that add up to the final cost. Here is a summary of these factors and an explanation of their typical costs:

Material

One major cost element is the kind of material utilized for the pump shaft. A typical pump shaft consists of guiding bearings, a protective sleeve, and a supporting component. Various types of pump shaft sleeves and bearing materials are utilized depending on the application. Bronze, carbon steel, and stainless steel are typical materials. The selected material must be resilient to the corrosive and abrasive properties of the fluid it is pumping. You may choose the material according to what you need.

Also, the pressure and operating environment determine the material choice. Generally, premium materials cost more. Effective cost management can be attainable through evaluating the requirements of the application and selecting the right material.

Size And Length

Pump shafts are available in various lengths and sizes. A pump’s shaft dimensions might change based on the size and particular type of the pump. However, a few standard dimensions are frequently used in pump shaft designs. Pump shafts typically have a diameter of 0.5 to 6 inches. Also, depending on the application, the pump shaft’s length may vary significantly. It usually falls between 3 and 36 inches.

Shafts may also feature splines or keyways for attaching to couplings or impellers, among other parts. Costs are higher for larger and longer pump shafts because they require more material and machining.

Manufacturing Process

The pump shaft’s manufacturing process may have an impact on its price. The production process includes precision machining, heat treatment, and floor finishing to guarantee the required mechanical systems and surface characteristics.

The procedure (such as casting, machining, or forging) determines the cost. The cost of machining is typically higher, particularly for intricate designs or requirements requiring precision.

Surface Finish

Everyone prefers a smooth finish pump shaft. Making the surface of the pump shaft and its parts smoother helps to reduce damage and rubbing. This makes it easier for the pump to work properly. Also, it makes sure the pump is sealed tightly, reduces the risk of rust, and makes the pump work better overall. It could lead to higher prices compared to rough surface shafts.

Customization

Pump shafts that are specially made to meet certain needs could be more expensive than standard options. Additional design, engineering, and production procedures are frequently needed for customization. Pump shafts can be customized or modified to meet the needs of certain uses.

You can change pump shafts to fit different needs. Some changes include making the shaft thicker or longer, adding slots or ridges to connect it to other parts, or putting on special coatings to protect it from damage. Also, the shaft can be shaped to fit extra gadgets or tools by cutting slots, holes, or threads into it.

Quality Standards

Higher expenses may result from the additional testing and quality control procedures required for pump shafts made to fulfill specified specifications.

While adhering to international quality standards and certifications may result in greater production costs, their improved quality and dependability may also serve as a justification for higher prices.

Labour Costs

Labour costs also play a crucial role in the cost determination of pump shafts. Accurately machining and fabricating pump shafts requires highly skilled expertise. In general, labor costs consist of pay, benefits, and overhead. Depending on the workforce’s level of experience and the area, it may differ.

Volume And Demand Cost

Economies of scale affect pump shaft costs. Larger production volumes or more demand may result in cheaper costs per unit because of purchasing and manufacturing efficiencies. On the other hand, decreased demand or smaller order sizes could lead to more expensive units.

Supplier And Location Cost

Pump shaft costs are affected by the supplier’s location and choice. Depending on the supplier’s location and business methods, many factors affect transportation costs, labor charges, taxes, and overhead.

Moreover, transportation expenses for semi-finished, final, and raw materials to and from manufacturing sites might affect costs, particularly in cases where there are logistical difficulties or long distances to cover.

Conclusion

In summary, it is difficult to determine the exact cost of the pump shaft. It can vary depending on the above-given factors and your needs. But you can get a pump shaft at the best price from a reputable manufacturer. Bhansali Techno Components is one such precision components manufacturer in India. These pump shaft manufacturers can offer a wide range of products at a very affordable price. You can contact them to finish your project at a decent cost.