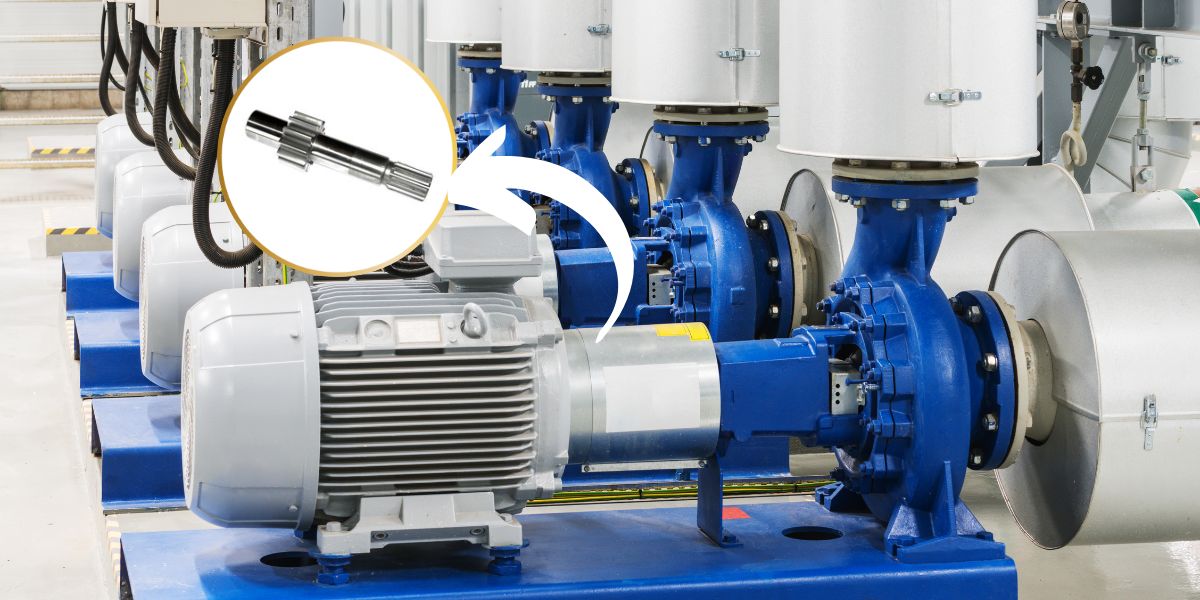

An Overview Of Shaft Sleeve In Pump

Are you tired of your pumps and compressors being exposed to rust and dust? Is there a viable solution for it? Well, a standard shaft sleeve in pump is all that you need.

A shaft sleeve refers to a hollow metal tube that has a cylinder-like shape. It is mounted over a shaft and shaft assembly. Such mounting is done so that it can be protected against any erosion or corrosion that is likely to occur in the due course of action.

Shaft sleeves find their most common use in single-stage pumps. The shaft sleeve in pump acts as a coverage or shield for the shaft assembly in various pumps and compressors. The pump shaft is responsible for protecting against erosion and corrosion.

Let’s further explore deep details about shaft sleeves in a pump through this article:

Types And Benefits Of Shaft Sleeve In Pump

The types of pump shaft sleeves you choose for your work will ensure longevity and quality. Hence, it would help if you got your hands on the best one from certified manufacturers or providers. Here are some types of shaft sleeves commonly used in pumps:

Metal Shaft Sleeve

These sleeves are typically made of materials like stainless steel, bronze, or other corrosion-resistant metals. They provide excellent protection against wear caused by abrasives or corrosive fluids.

Ceramic Shaft Sleeve

Ceramic sleeves offer superior resistance to abrasion and corrosion compared to metal sleeves. They are often used in pumps handling highly abrasive slurries or corrosive chemicals.

Teflon (PTFE) Shaft Sleeve

Teflon sleeves provide excellent chemical resistance and low friction properties. They are suitable for pumps handling corrosive chemicals where contamination from metal components must be avoided.

Composite Shaft Sleeve

Composite sleeves are made from a combination of materials such as fiberglass, carbon fiber, or epoxy resin. They offer good resistance to both abrasion and corrosion and are often used in applications where cost-effective solutions are required.

Hardened Shaft Sleeve

Some pump applications require shaft sleeves made from hardened materials such as hardened steel or chrome-plated steel to withstand extreme operating conditions and abrasive fluids.

Sleeve With Coatings

Certain shaft sleeves are coated with specialized materials like ceramic coatings or polymer coatings to enhance their resistance to wear, corrosion, and chemical attack.

The best tip for you to make the buying decision is after looking at the quality of sleeves offered. Pump shaft manufacturers like Bhansali Techno Components, who make it from the best quality raw materials, will provide you with relevant information.

Usually, the types of pump shaft sleeves that are available in the market and their benefits are as follows:

- Standard shaft sleeve

- Renewable shaft sleeve

- Screwed shaft sleeve

- Spacer shaft sleeve

Let’s uncover the generic benefits of shaft sleeves in a pump. They can be effectively placed around the piping surface. The modules are practical. Also, the reliance is top-notch as it suits the purpose and requirements of different systems. The best part about them is that they are cost-effective. They ensure an easy-to-work-with environment.

However, you must see that you are getting them from the right manufacturers, like Bhansali Techno Components. They ensure that the products are offered to the customers after rigorous testing and screening processes.

Different Types Of Pump

Likewise, pumps are of different types. Seamless pumps and mechanically sealed pumps are the division of pumps. Let’s know about them in more detail.

Mechanically Sealed Pumps

They come with a closing device that ensures a physical block to the fluidity of liquids and air. It ensures that the air and fluids cannot quickly move in and out of the pump.

Sealless Pumps

However, the sealless pumps are the ones that don’t have this block, and the movement of air and fluids is free.

The shaft sleeves are connected and are great for use with a variety of devices. However, their most noticeable use is with typical applications like pumps and compressors. That’s why they are mainly called pump shaft sleeves. They act as a shield for the shaft seal and, hence, provide coverage to the surface so that it doesn’t experience any damage.

The primary function of a shaft sleeve is simple – to give protection. The sleeve renders protection to the running surface of the shaft seal. Also, it protects the surfaces that are in contact with any kind of danger and extends coverage from issues that can arise from exposure to abrasive wear.

Suppose you want to explore the benefits of these components offered by the precision components manufacturers. In that case, you have to figure out your need, as these sleeves are available in different sizes and forms, as discussed above.

Specifications And Features

Let’s learn about the specifications of the sleeves and their features that help in making a better buying decision:

Materials

The pump shaft sleeve is made of materials that feature strong and durable stainless steel construction. All these things are necessary for providing a corrosion-free and erosion-free sealing surface. The quality assurance is of the highest degree that can surpass the original shaft specifications, too. Also, quality control requires testing, and hence, you should ensure that the chosen manufacturers run through 100% inspection on the sleeve, especially on the critical dimensions.

Customizations

Also, the pump shaft sleeve customization requirements allow the manufacturers to serve the need. For example, they chose an ultra-thin construction of 0.25 mm. Such a construction allows the use of the original seal. Also, there is minimal additional lip loading.

Input Hardness

When you are getting the sleeve, you should consider the hardness of the material that is used to build it. It is essential as sufficient hardness will ensure proper functioning; otherwise, the shaft sleeve is most likely to fail. Also, the thermal expansion coefficient is a thing for consideration. The manufacturers need to ensure it while designing the pump shaft sleeve. Ideally, the thermal expansion coefficient should be equal to that of the shaft sleeve.

Difference Between Sleeves And Shaft Sleeves

Yes, you read that right. There is a difference between sleeves and shaft sleeves.

Sleeves

The sleeves are piping devices. Their primary role is to provide protection and strengthen the different pipelines through interconnectivity.

Shaft Sleeves

However, the shaft sleeves are hollow cylindrical tubes. They are usually made of metal. They are mounted over the shaft assembly as they ensure protection against corrosion. Also, they ensure that there is no damage when they are exposed to stress-induced environments.

The ones with ultra-thin components are the best picks to ensure coverage against leakage.

Conclusion

The shaft sleeve in the pump has an indispensable role to fulfill, and hence, there should be no compromises in its manufacturing. However, you might not have a hand in it. But you have to ensure that you are choosing manufacturers that strive to provide excellent quality products and that the rates are competitive yet reasonable.

The market is filled with random manufacturers. But, long-lasting functioning and results are offered by products given by manufacturers who meet national and international standards. Hence, choose a top-rated precision components manufacturer like Bhansali Techno Components to get the best products from certified and assured manufacturers.