An Overview Of High-Tensile Fasteners

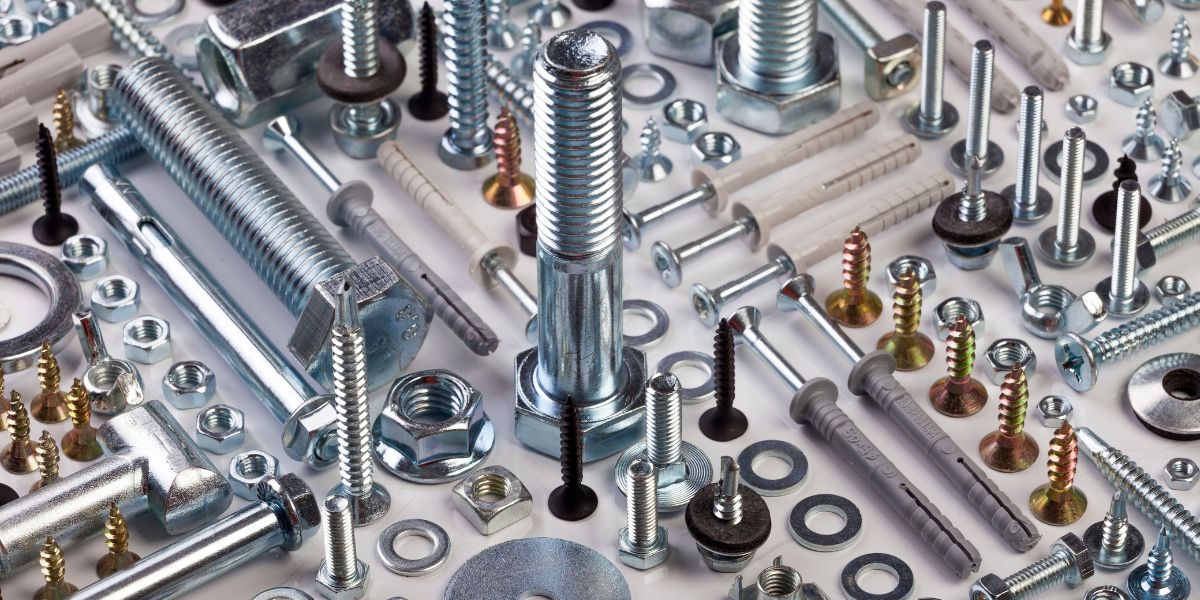

Wondering what is high-tensile fasteners? They are special bolts, screws, or studs made to handle high tension or pulling forces. They are frequently employed in situations where standard fasteners might break under severe pressure.

These fasteners are made up of heat-treated alloys or carbon steel. So, it has more strength than usual fasteners. This blog article will cover high-tensile fasteners and their applications across several sectors in great depth.

Here is a simple summary of high-tensile fasteners

High-tensile fasteners are similar to very strong fasteners such as screws, bolts, and nuts. They are made of hard steel, so even after repeated pulling or stretching, they won’t break.

These fasteners are perfect for jobs where safety and reliability are important because they clamp tight and can resist outside forces well.

These fasteners are useful in construction, making cars, and the manufacturing sector because they keep things secure.

Characteristics Of High-Tensile Fasteners

As you know about high-tensile fasteners, we move on to learn about their characteristics. High tensile fasteners have some important features, which are given below:

Corrosion And Chemical Resistance

These fasteners can handle tough environments like salty sea air, oily situations, or places with lots of chemicals without getting damaged. So, they are great for things like ships, oil rigs, or industrial settings where normal fasteners might only last for a while.

Low Friction

These fasteners are highly efficient, with a coefficient of friction as low as 0.02. So, you can use it more easily and efficiently as they eliminate resistance during assembly and operation.

Broad Temperature Range

These fasteners can tolerate temperatures between -420°F and +550°F (-250°C and 285°C), so you can count on them to perform dependably under challenging conditions.

Machinability

Since these fasteners are machinable, you may mill them to precisely your requirements after applying many coats of Xylan coating (available in most formulations).

High Wear Resistance

These fasteners show remarkable wear resistance even under high pressure. It guarantees their durability and dependability in demanding applications.

Weather Resistance

High tensile fasteners have a high level of resistance to weather-related factors like sunshine, sea, and road chemicals.

Adaptable Curing Schedule

It is possible to cure them at room temperature or as high as 750°F (400°C). It increases your flexibility while the product is being produced.

Flexibility

Many Xylan coatings are flexible and durable enough to bend easily and frequently without breaking.

Longevity

The salt spray SST life of these fasteners is more than 1000 hours. It demonstrates their resilience in corrosive and hostile conditions.

Specifications Of High-Tensile Fasteners

Along with characteristics, it is critical to know the specifications of high-tensile fasteners. The following are typical high-tensile fastener specifications:

| Type | Specification |

|---|---|

| Grades | 4.6, 4.8, 8.8,10.9, 12.9 |

| Standard | DIN, ASTM, BS, and some other international standards |

| Size | Custom Sizes (M3 – M56 | 3/6″ to 2″ ) |

| Length | 3mm to 200 mm |

| Finish | Hot Dip Galvanized, Plain, and Zinc Plated |

Advantages Of High Tensile Fasteners

In difficult conditions, when strength and durability are essential, high-tensile fasteners are effective. They offer several benefits compared to regular fasteners. A few benefits they offer are as follows:

- Fasteners with high tensile strength may tolerate increased strain and shear pressures. So, they are ideal for applications where ordinary fasteners could break.

- Smaller, lighter fasteners can sustain larger loads. You may often use them to reduce the total weight of structures and machines.

- These fasteners are really strong and don’t break easily under pressure. This keeps the machinery, buildings, and equipment strong and safe.

- Even though they are expensive, you can use fewer high-tensile fasteners than normal fasteners in a project. This could result in lower labour and material expenses.

- Compared to ordinary fasteners, these fasteners last longer. So, there is no need to replace or repair it often.

High-Tensile Fasteners Uses

High-tensile fasteners are reliable and durable. Any industry where stronger products are required can use it.

Here, we observe how certain industries meet their needs by using high-tensile fasteners:

Automobile Sector

High-tensile fasteners are used in the automotive industry to keep sections of vehicles together. They resemble extremely strong screws or bolts. High-tensile are utilized in the suspension, frame, and engine parts. They ensure that the vehicle is secure and lasts a long time.

Manufacturing Sector

In this industry, these tough fasteners are used to build big machines and industrial equipment. They are tough and reliable, making sure industrial equipment works securely.

Construction Industry

Extreme loads and stress are not a problem for high-tensile fasteners. They can withstand the strain and weight that big structures put on them over time because of their extraordinary strength.

High-tensile fasteners offer the base of strength that enables these structures to remain constant, whether a high-rise building standing tall against the forces of nature or a suspension bridge handling steady traffic.

Marine Industry

In this maritime sector, strong fasteners can hold parts of ships and structures in place. These fasteners are tough enough to handle tough weather and salty water without getting damaged.

Oil And Gas Sector

You can use these strong fasteners to build pipelines, rigs, and other important things in the oil and gas industry. They can handle high pressure and not get damaged by rust or corrosion.

Railway Industry

You can use these fasteners in the railway sector to secure components and tracks. It guarantees the stability and safety of rail systems.

Mining Sector

You can use high-tensile fasteners in mining equipment. They are tough enough to handle the heavyweights and tough conditions of mining operations without breaking.

Conclusion

In summary, high-tensile fasteners can work even in tough scenarios where ordinary fasteners would fail. But remember that you must buy these fasteners from the top producers of high-tensile fasteners for your projects to achieve excellent results.

Within the high tensile fasteners manufacturers, Bhansali Techno Components is a reliable manufacturer of precision components. They supply a wide range of high-tensile fasteners in different grades to satisfy your unique needs. You can trust them and make your project very successful.